(19 products available)

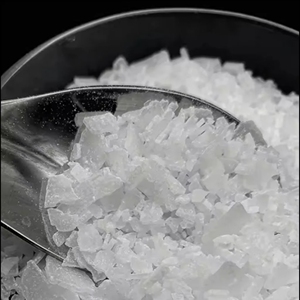

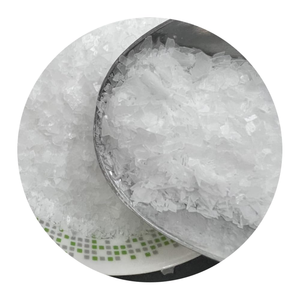

VPEG and HPEG are used in making concrete admixtures to improve concrete performance. These PEGs are used to develop PCEs, which are known as second-generation superplasticizers. They offer a high water reduction rate and a long workability retention period.

VPEG and HPEG are popular due to their sustainability and efficiency. Besides, they can be customized to suit specific requirements. Below are the types of VPEG and HPEG for concrete admixture:

Polymer admixtures are essential in concrete construction because they help improve the performance and durability of concrete. Some of their functions include:

Cold Weather Concreting

When temperatures drop near or below freezing, VPEG admixtures can help. They speed up the setting so concrete hardens quickly in the cold. This is important for preventing damage from frost.

High-Strength Concrete

Adding VPEG increases the strength of the cured concrete. HPEG admixtures make concrete stronger, allowing for thinner slabs in buildings while still meeting strength requirements. This strength boost is useful for structural elements like beams and bridges.

Fast-Track Construction

Construction projects that need to be finished quickly can benefit from accelerated concrete curing with VPEG admixtures. This reduces the time spent on curing concrete so that subsequent construction steps can be completed faster.

Hot Weather Concreting

When concrete is poured in hot, sunny conditions, HPEG admixtures help keep the fresh concrete cool and workable. They slow down the setting time so that concrete can be placed and finished properly before it starts to harden in the heat.

Mass Concrete Pouring

Large pours, like for foundations or mat slabs, require careful temperature control to prevent cracking. VPEG admixtures work well for this type of placement. They produce a concrete mix that stays stable and workable over long pouring times while generating less heat of hydration.

Durable Concrete

Concrete that will be exposed to harsh conditions, like saltwater or chemicals, needs to last a long time. VPEG admixtures help achieve this durability. The resulting concrete has a lower permeability, preventing water and contaminants from damaging the internal structure over decades of use.

High-Performance Concrete

Concrete used for high-end applications, like skyscrapers or parking garages, needs to be top-notch. VPEG and HPEG admixtures deliver. Their combined effects result in concrete with exceptional strength, workability, and longevity that meet the most demanding design requirements.

Consider these factors when buying vpeg and hpeg resins for sale:

Compatibility with Concrete Mixtures

The first step is to ensure the vpeg hpeg is compatible with the concrete mixtures. This is crucial because it determines whether the additives will work as expected. The seller should check the technical data sheets to determine the recommended admixture for each PEG variant. They can also consult with suppliers for compatibility testing and recommendations.

Performance Requirements

The buyer should determine the performance requirements for each concrete application. For example, if they need high-strength concrete, water-reducing admixtures, or accelerated setting times, they should look for PEGs suitable for those applications. Suppliers provide detailed information on the performance characteristics of each PEG variant.

Regulatory Compliance

Buyers should ensure that the vpeg and hpeg resins comply with local regulations. This is important, especially for projects in environmentally sensitive areas. It ensures that the selected resins are safe for use and won't negatively impact the environment. The resins are generally safe when they undergo proper treatment and processing.

Cost Considerations

The buyer should balance cost and quality when choosing a concrete admixture supplier. While competitive pricing is important, they shouldn't compromise quality. This is because substandard products can lead to increased costs in the future due to project delays or compromised concrete quality. They should look for a supplier with reasonable prices and excellent customer service.

Supplier Expertise and Support

The buyer should look for a supplier with extensive experience in the industry. An ideal supplier will provide concrete solutions tailored to specific needs. More importantly, they should offer technical support throughout the project to ensure everything runs smoothly.

Q1: What are vpeg and hpeg?

A1: Vpeg and hpeg are polyols used in the production of concrete superplasticizers. They help reduce the water-cement ratio in concrete mixtures, improving workability and flow.

Q2: How is vpeg hpeg mixed with cement?

A2: Vpeg and hpeg can be mixed with cement in a concrete batching plant. They should be mixed thoroughly to ensure even distribution in the concrete mixture.

Q3: What is the shelf life of vpeg and hpeg?

A3: The shelf life of vpeg and hpeg depends on storage conditions. When stored in a cool, dry place, they can last for several months. It is essential to check for any signs of degradation before use.

Q4: Can vpeg and hpeg be used in hot weather?

A4: Yes, vpeg and hpeg can be used in hot weather. They help reduce the heat of hydration in concrete, making it suitable for hot weather conditions. However, it is essential to follow the manufacturer's guidelines when using them in hot weather.

Q5: Are vpeg and hpeg harmful to human health?

A5: Vpeg and hpeg are not harmful when used appropriately. However, it is essential to wear protective gear when handling them to avoid any skin irritation.