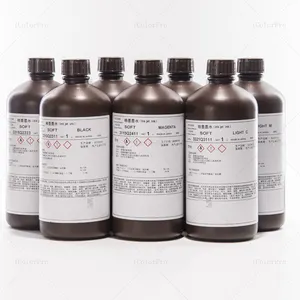

Toyo UV Printing Ink: Revolutionizing Print Quality

Toyo UV Printing Ink represents a major advancement in the world of printing technology, designed specifically for modern printers that demand high-quality results. This type of ink uses UV-light curing technology to dry instantly when exposed to ultraviolet light, eliminating the waiting time associated with traditional inks. As businesses and manufacturers move towards more efficient production methods, Toyo UV Printing Ink meets the need for speed without sacrificing quality.

Types of Toyo UV Printing Ink

Understanding the different types of Toyo UV Printing Ink available can significantly enhance your printing experience. Here are the primary categories:

- Flexible UV Inks: Ideal for applications that require bending or stretching, such as packaging materials.

- Rigid UV Inks: Suited for solid surfaces such as plastics and metals, providing a durable finish.

- Specialty UV Inks: Incorporates unique characteristics like metallic or fluorescent effects for added visual appeal.

- Eco-Friendly UV Inks: Formulated with sustainable materials that reduce environmental impact while maintaining high performance.

Applications of Toyo UV Printing Ink

Toyo UV Printing Ink is widely used across various industries, providing multiple applications that cater to different needs. The versatility of this ink makes it ideal for:

- Packaging: Essential for vibrant and durable packaging solutions that attract customers.

- Labeling: Perfect for producing eye-catching labels that withstand environmental factors.

- Signage: Used in the creation of outdoor signs and banners that require resilience against the elements.

- Decorative Printing: Provides stunning visuals for decorative items, textiles, and promotional products.

Features and Advantages of Toyo UV Printing Ink

The features of Toyo UV Printing Ink contribute significantly to its growing popularity in the printing industry. Users benefit from several advantages:

- Fast Cure Time: UV inks dry instantly under UV light, speeding up production times and enhancing workflow.

- High Color Saturation: Produces vibrant colors that stand out, increasing the appeal of printed materials.

- Durability: Resists scratches, chemicals, and fading, ensuring long-lasting quality.

- Print on Various Substrates: Capable of printing on a wide range of materials, including paper, plastic, and metals.

- Reduced Waste: Instant curing minimizes ink pooling and allows for precise control, leading to less waste and a more economical process.