Introduction to Surface Grinders Used

Surface grinders are indispensable tools in the machining industry, designed for precision grinding of flat surfaces. The versatility and accuracy of these machines make them essential in a variety of applications. Whether for deburring, smoothing edges, or enhancing overall surface finish, surface grinders used in manufacturing are known for their reliability and effectiveness.

Types of Surface Grinders Used

- Horizontal Spindle Surface Grinders: These models operate with horizontal grinding wheels, offering excellent finishing capabilities. Commonly used for flat surfaces, they are well-suited for high-volume production.

- Vertical Spindle Surface Grinders: Featuring a vertical grinding wheel, these grinders are ideal for smaller workpieces or intricate detailing. Their design allows for quick changeovers and enhanced accuracy in shallow grinding tasks.

- Reciprocating Surface Grinders: Known for their back-and-forth motion, these grinders are perfect for larger, heavier workpieces. The reciprocating action provides uniform material removal over larger areas.

- CNC Surface Grinders: Integrating computer numerical control, these grinders enable automated operation, thus increasing precision and reducing human error. They are particularly favored in industries that require repetitive machining tasks.

Applications of Surface Grinders Used

- Metalworking: Surface grinders are widely used in workshops for grinding a variety of metals, providing a smooth finish and precise dimensions critical for components.

- Tool and Die Making: Essential in the creation of molds and dies, surface grinders cater to the strict tolerances required in toolmaking with exceptional repeatability.

- Aerospace and Automotive Industries: Surface grinders ensure high precision for parts used in safety-critical applications, thereby enhancing performance and reliability in every finished product.

- Manufacturing: Many manufacturers employ surface grinders in their operations to maintain tight tolerances and improve the surface quality of components, enhancing overall production efficiency.

Features and Advantages of Surface Grinders Used

- Highly Precise Grinding: With defined tolerances, surface grinders deliver exceptional flatness, parallelism, and surface finish.

- Versatility: Capable of grinding a wide range of materials and shapes, surface grinders can easily accommodate various tasks within a single machine.

- Efficient Operation: With advanced technology and automation options, surface grinders have significantly improved efficiency, reducing time and labor costs for manufacturers.

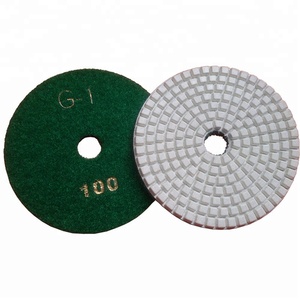

- Reduced Wear and Tear: Utilizing high quality grinding wheels and durable construction materials enhances the longevity of surface grinders, minimizing maintenance needs.

- Enhanced Safety Features: Modern surface grinders come equipped with safety mechanisms to protect the operator and ensure safe working conditions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4