Introduction to Support Pipeline

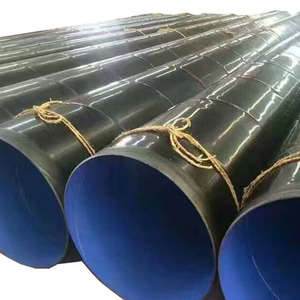

The support pipeline is an essential component in various industrial applications, providing critical stability and organization for piping systems. Designed to hold and support pipes securely, these systems ensure the integrity and functionality of various infrastructures, from water supply networks to oil and gas transport. With a variety of configurations and materials available, understanding the nuances of support pipeline systems is key for professionals in engineering, construction, and maintenance.

Types of Support Pipeline

Support pipelines can be classified based on their design and application, ensuring a precise fit for every project. The main types include:

- Pipe Hangers: These are used to suspend pipes from ceilings, providing vertical support.

- Pipe Supports: Offering a solid base, these are installed at the bottom of the pipes to bear their weight.

- Brackets: Metal or plastic brackets can stabilize pipes along walls and help with alignment.

- Clamps: These secure pipes in place, preventing movement and potential damage during operation.

- Flexible Supports: Allowing for thermal expansion, these are crucial for systems exposed to temperature changes.

Applications of Support Pipeline

Support pipeline systems play a vital role across various industries due to their ability to stabilize piping and enhance system performance. Common applications include:

- Hydraulic Systems: Support pipelines ensure the smooth flow of fluids within hydraulic machinery, maintaining pressure and flow integrity.

- Oil and Gas: In the petroleum industry, robust support systems are crucial for transporting hydrocarbons safely and efficiently.

- Water Treatment Plant: Ensuring reliable pipe organization is essential for the effective treatment and distribution of water.

- Manufacturing: In many factories, support pipelines streamline the management of both raw materials and products.

- HVAC Systems: Properly supported ductwork is essential for maintaining efficient heating and cooling in buildings.

Advantages of Using Support Pipeline

Implementing a strong support pipeline system brings numerous benefits that enhance both safety and efficiency:

- Increased Safety: By ensuring pipes are firmly held in place, the risk of leakage and accidents is substantially reduced.

- Improved Maintenance: With a well-organized pipeline, maintenance crews can quickly identify issues and perform necessary repairs.

- Cost-Effectiveness: Proper support systems reduce wear and tear on pipes, extending their lifespan and minimizing replacement costs.

- Enhanced Performance: Stabilizing pipelines leads to smoother operations, reducing noise and vibration during usage.

- Flexibility: Various support types cater to different needs, making it easier to adapt to changing industry requirements.