(3075 products available)

A soap box mould is a packaging tool used to create soap bars. It shapes the soap, ensuring it fits nicely in the box. There are various kinds of soap box moulds, each with distinct benefits and features to suit different needs and preferences.

Single cavity soap mold

This mould has one cavity. It is simple and makes one shape at a time. It is good for beginners or people who want to make unique soaps, like glycerin soap molds for embedding.

Multi cavity soap mold

This mould has many cavities. It saves time by making several soaps of the same kind at once. Each cavity has the same shape and size. It is ideal for making popular soap bars.

Silicone soap mold

Silicone molds are flexible and easy to use. They can be single or multi-cavity. The silicone material allows for easy popping out of the finished soap without damaging it. Silicone soap molds can make complex designs with sharp details. They are suitable for cold process soap making. They come in different shapes, such as round, square, and heart.

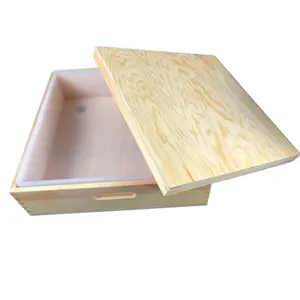

Wooden soap mold

Wooden molds are traditional and great for making large batches of soap. They often come with liners to make removing the soap easier. These molds are perfect for loaf-style soaps that can be cut into bars.

Polycarbonate soap mold

These molds are hard and clear. They are perfect for making soaps with a shiny, glossy look. They are also good for making designs with layers. They are durable and give exact shapes.

Embossed soap mold

These molds have patterns or designs built into them. They leave an imprint or design on the top of the soap. They are great for branding or adding a decorative touch to the bars.

Column mold

Column molds make soap in a cylindrical shape. These molds are often used for making pillar-style soaps or embedding other soap inside a column.

Roll-out soap mold

These soap molds come with a special feature that allows the soap to be easily rolled out after it has set. This is particularly useful for removing soaps without damaging the mold or the soap bars.

The design of the soap box moulds focuses on creating a functional and aesthetically pleasing packaging that meets the needs of both manufacturers and consumers. There are some important aspects to consider in the design of soap box moulds.

Personal Care Industry

Wholesale moulds for soap cases can help companies make packaging for a wide range of bathing soaps, including anti-bacterial soap, natural soaps, and herbal soaps.

Cosmetics and Skincare Products

These moulds create unique packaging for facial cleansers, hand soaps, and different kinds of skincare bar products.

Luxury Hotel and Resort Industry

Hotels and resorts can use soap box moulds to create custom packaging for branded soaps offered in guest bathrooms. The packaging increases brand awareness and gives guests a luxury experience.

Gift and Specialty Soap Businesses

Custom soap box moulds enable the creation of unique packaging for artisanal soaps. Packaging with special designs and shapes can attract customers in a competitive market.

Food Industry

In the food industry, soap box moulds can produce packaging for food items like candies and chocolates. The moulds can make boxes with unique shapes and appealing designs that attract customers.

Pharmaceutical Industry

Soap box moulds can create packaging for medicated soaps, topical soap treatments, and other pharmaceutical soap products. With the moulds, the boxes can have clear labelling and product information for safe use.

Craft and DIY Projects

The moulds enable the production of packaging for handmade soaps and other custom soap creations. The moulds are great for creating unique, one-of-a-kind packaging that suits individual artistic visions.

Wholesale buyers need to consider these factors when choosing soap box moulds for their customers.

Customer Target Market

Wholesale buyers should know the customer base of the soap brands they supply. Find moulds that fit the customers' tastes and preferences. For example, organic customers want moulds that have simple, natural designs. Customers who target a luxury market need moulds with unique shapes and detailed branding.

Production Efficiency

The speed of mould production affects the time-to-market for soap brands. Choose moulds with features like smooth release and interlocking parts to speed up production. Also, pick durable moulds that can withstand the rigors of an production line. Such moulds will have a longer lifespan and reduce the cost of mould replacement.

Material Compatibility

Pick moulds that are compatible with the materials used to make soap. Some moulds work well with soft soap materials. Others suit harder soap formulations better. Ensure that the mould materials can withstand the heat and pressure of casting. For example, metal moulds are good for high-temperature plastics. Silicone works well for encapsulation and low-temperature casting.

Market Trends

Stay updated on trends in soap packaging. For example, there is a rising demand for sustainable packaging. This trend may lead to a greater need for moulds that make boxes with recycled paper. There may also be trends that increase the demand for certain shapes or branding features. Knowing trends will help mould makers and soap brands stay ahead of the competition.

Q1. What are the benefits of using a soap box mould?

A1. Using a soap box mould can improve production speed, reduce costs, create consistent products, and simplify the packaging process.

Q2. What kinds of materials are soap box moulds made from?

A2. Soap box moulds can be made from metals like aluminum and steel, as well as plastics and composites.

Q3. Can soap box moulds be customized?

A3. Yes, many soap box mould manufacturers offer customization options to create moulds that meet specific needs and preferences.

Q4. How do metal soap box moulds benefit the production process?

A4. Metal soap box moulds are durable, can withstand high pressures, and are suitable for producing large quantities of boxes quickly.

Q5. How should soap box moulds be stored?

A5. When storing soap box moulds, make sure they are clean, dry, and properly covered to protect them from dust, moisture, and damage.