(7568 products available)

There are different types of scaffolding and shoring jacks available in the market. Each type has unique features that make them suitable for specific applications. Below are the major types:

Scaffolding Jacks

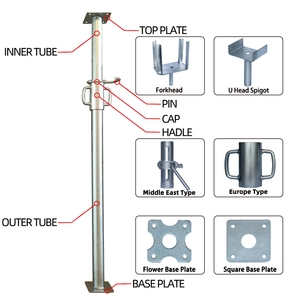

Scaffolding jacks are equipment used to support temporary platforms that help in lifting construction materials and crew during construction projects. They are vital in providing stable and adjustable support to the scaffolding system. Scaffolding jacks are equipped with a telescoping post that is usually made of galvanized steel or aluminum. The post is adjustable and fitted with a locking mechanism for stability and strength.

The jacks are also designed with a screw-adjustable top plate that enables precise height adjustments. Additionally, they come with a load-bearing capacity of up to 10 tons, meaning they can support more weight. The scaffolding jacks are popular due to their ease of installation and maintenance. They are also versatile and provide enhanced stability and safety.

Shoring Jacks

Shoring jacks, also known as shore jacks, are used to provide temporary support to structural elements in construction projects. They support beams, walls, and slabs. Shoring jacks are designed to transfer the load to the ground safely. They have a strong and robust construction for enhanced strength and stability.

The jacks are usually made of powder-coated or galvanized steel, which has high tensile strength. The jacks also feature a base plate, a telescoping tube, a top plate, and a saddle. They are popular due to their ease of installation and adjustment. Shoring jacks are mostly used in propping, permanent bridging, and temporary shoring operations.

Telescopic Jack

Telescopic jacks are support devices with multiple tubes that slide inside one another. They extend and retract to reach different heights. The jacks are commonly used in scaffolding, shoring, and lifting applications because of their height adjustability. They consist of a locking mechanism that enables quick height adjustments.

The locking mechanism ensures the stability and safety of the load when lifted. They are also designed with a strong base plate that distributes the load pressure evenly on the ground. Telescopic jacks are popular because of their high load capacity and excellent corrosion resistance.

Scaffolding shoring jacks provide support to structures during construction. They are also used to support beams and columns when lifting them to the desired height. These jacks are essential in the construction industry. They provide a safe and stable platform for workers to do their work. Let's look at the features of shoring jacks.

Adjustability

Shoring jacks are adjustable. They have a telescoping frame that can be extended or contracted depending on the needs of the project. The jacks can be adjusted to fit different heights and widths. This ensures that they provide the necessary support. The jacks can also be adjusted to accommodate uneven or rough terrain. This guarantees a stable and secure platform for construction.

Load-bearing capacity

Scaffolding shoring jacks can accommodate a lot of weight. They are constructed with high-strength materials. This includes steel and aluminum. The jacks can support loads of up to several tons. Their load-bearing capacity provides stability and safety to construction sites.

Easy installation

Shoring jacks are easy to install. They have a simple design that consists of a vertical post, an adjustable jack, and a base plate. The vertical post and base plate provide support and stability. The base plate spreads the load over a larger area. This prevents the jacks from sinking into the ground. Once the base plate is positioned correctly, the vertical post is then screwed into the jack. The post is then adjusted to the needed height, and construction can begin.

Durability

These jacks are durable and long-lasting. They are made of high-quality materials, ensuring they withstand everyday use and harsh weather conditions. Their materials prevent corrosion, which enhances their lifespan.

Versatility

Shoring jacks are versatile. They are used in different industries, such as construction, mining, and maintenance. They can be used for different construction projects, such as shoring, scaffolding, and lifting operations.

Scaffolding shoring jacks are used in construction to help support and stabilize structures during the construction process. They are used in different ways, including:

Supporting beams and columns

Shoring jacks can be used to support beams and columns in construction sites. These jacks help to stabilize and support the structural members until they are fully erected. The jacks can be adjusted to fit different heights and are placed under the beams and columns to support them.

Temporary support of walls

During construction or renovation, walls may need to be temporarily shored up to ensure structural integrity. Scaffolding jacks can be positioned at regular intervals to bear the load and prevent wall collapse.

Jack support for formwork

When pouring concrete for slabs, arches, or other structures, shoring jacks can support the formwork. This ensures that the concrete sets in the desired shape without collapsing under its weight during the curing process.

Heavy load lifting and positioning

Hydraulic jacks can lift and position heavy loads, such as steel girders, precast concrete elements, or heavy machinery during installation. The high weight capacity ensures safe lifting and placement of these components.

Restoration and underpinning projects

In building restoration projects, shoring jacks may be used to support the structure while historical elements are carefully removed and restored. Additionally, in underpinning projects where the foundation is strengthened, shoring jacks temporarily support the structure until new foundation elements are installed.

Shoring jacks in excavation

Excavating a building's foundation involves removing soil and rock, which can destabilize adjacent walls and structures. Shoring jacks can support nearby walls or existing foundations to prevent collapsing during excavation. They are also used to support the walls of the excavated site to prevent caving in.

Adjustable roof support

In construction projects involving the installation of roofs, shoring jacks can temporarily support roof trusses or rafters until they are securely tied to the walls or other supporting structures. Roof construction often involves heavy materials and requires proper support during assembly.

Construction project managers often look for scaffolding shoring jacks that will meet the demands of their upcoming projects. Here are some considerations that can help buyers select the appropriate shoring jacks.

Load capacity. The load capacity is the amount of weight the shoring jack can support. Different kinds of shoring jacks have different load capacities. For instance, the screw jacks can be built to support a specific load or can be used to stabilize and support loads of up to 60 tons or more. It is important to choose a jack with a load capacity that exceeds the expected load to prevent accidents.

Height adjustment. Construction workers often use shoring jacks to support structures at different heights. Therefore, it is important to choose a supporting jack that can be easily adjusted to the required height.

Material and durability. Shoring jacks are subject to wear and tear due to environmental conditions and exposure to elements. It is, therefore, important to choose scaffolding jacks made from quality materials, such as carbon steel, that can withstand high loads and are rust-resistant.

Base plate and mounting options. The base plate is the component that rests on the ground, and the mounting option is the attachment that connects the shoring jack to the structure being supported. It is important to consider the base plate and mounting options when buying shoring jacks because they provide stability and distribution of weight. Choosing the right base plate and mounting option provides safety and prevents accidents.

Portability and storage. Portability and storage are important factors when choosing shoring jacks because they affect how easily the jacks can be moved from one place to another and how they can be stored when not in use. Buyers should consider the weight of the jacks, the type of material used to manufacture them, and the size when collapsed or assembled for storage.

Regulations and certifications. It is important to choose shoring jacks from manufacturers who adhere to industry regulations and standards. Such manufacturers produce jacks that are safe for use and have the required certifications.

By considering the factors above, buyers will select shoring jacks that are safe, durable, and suitable for their construction needs.

Q1: What are the load capacities of shoring jacks?

A1: The load capacity varies by design. For example, single telescopic jacks can support up to 30 tons, while double-shock jacks offer a capacity of up to 40 tons. However, some jacks can be manufactured on demand with higher load capacities.

Q2: What materials are shoring jacks made of?

A2: Most shoring jacks are made of steel, which is known for its strength and durability, or a combination of high-strength steel and concrete for added rigidity.

Q3: How is the length of shoring jacks adjusted?

A3: Shoring jacks have telescopic sections that can be extended or retracted to adjust the length. The length is adjusted by locking the sections using the appropriate shoring jack threaded collar or nut.

Q4: How to maintain shoring jacks for durability?

A4: Proper maintenance involves regular inspection, cleaning, lubrication, and replacing any worn-out or damaged parts. Also, following the manufacturer's guidelines and keeping the shoring jack in a dry place will ensure it lasts longer.

Q5: Are shoring jacks reusable?

A5: Yes, shoring jacks are reusable. They can be used for multiple construction projects if properly maintained and stored.

The keyword "scaffolding shoring jack" maintains a consistent average monthly web search volume of 10, showing no significant change over the past year or even over the last three months. The web search volume data for each month from December 2023 to November 2024 consistently reports the same figure of 10 web searches.

This keyword exhibits a stable trend with no peaks or valleys, indicating a steady interest level without any fluctuations or seasonal variations. The data reflects a niche but steady demand for this specific type of construction equipment, with web searches evenly distributed throughout the year.

The consistent web search volume suggests a stable market demand, likely driven by ongoing construction projects and the need for reliable scaffolding solutions. This steady demand could be attributed to the essential role that scaffolding shoring jacks play in construction and real estate projects, ensuring safety and efficiency in building processes.