(34125 products available)

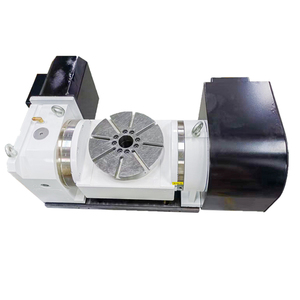

A rotary table machine is a piece of equipment used for rotating workpieces and is one of the key components of rotary table welding machines. The rotary table machines comes in several types.

Rotary tables for nozzles

Nozzle rotary table machines are designed to weld complexes shaped workpieces, such as pipe nozzles or branches, at angle junctions. The workpiece is fixed on the table while the welding head moves along a preprogrammable path to perform the weld. Nozzle rotary tables often have indexing systems that allow precise positioning of the workpiece for welding at specified angles.

Rotary tables with positioners

Positioner rotary tables machines are equipped with an additional mechanism (a positioner) that can tilt or move the workpiece. Change the welding head's orientation. This allows welding of workpieces in different planes without repositioning them. Rotary tables with positioners are versatile and suitable for welding various complexes and shaped assemblies.

Automatic feeding of rotary tables

Such tables are fitted with an automatic feed mechanism that continuously feeds the workpiece for welding without interruption. This increases the welding efficiency and quality of work. Rotary tables with automatic feed are suitable for welding large-scale production and require constant feeding of workpieces.

Tilt rotary tables

It allows the workpiece to be tilted at a specified angle during welding. This positions the workpiece better for welding complexes-shaped joints or increases the welding operator's accessibility to the welding area. Tilt rotary tables are suitable for joining complexes shaped assemblies or considering the welding operator's accessibility to the welding area. They can be used with different types of welding methods.

These are just a few examples of the different kinds of rotary tables which are typically employed in welding operations. Each type of rotary table is designed to meet specific needs and is used in various industries.

Packaging

Rotary table packaging ensures safe transport and protects the product from any possible damage. Usually, manufacturers use wooden cases for packaging. Sometimes products are packaged additionally in stretch films. Make sure the packaging materials are suitable for the product and do not cause any damage when packaging or unpacking.

Product Weight

The weight of those machines depends on the rotary table dimension and material. Also, the weight is affected by the max load of the rotary table and whether it is manual or automatic. Clients can find tables with a weight of from several kilograms to several hundred kilograms.

Product Dimensions

The diameter or length of the rotary table ranges from a few hundred millimeters to several thousand millimeters. The height varies from a few hundred millimeters to over a thousand millimeters as well. The dimensions mostly depend on the workpiece the machinery is designed to process.

Maintenance

It is integral to maintain those machines in order to use them for a long time period. Lubrication is one of the most important tasks. It is crucial to ensure that bearings, gears, actuators, and other moving components work properly and are free from wear and tear. Also, it's important to clean rotary tables regularly to remove any dust, residue, and chips. Once every few months or weeks depending on how often the machine is used, your tables should be inspected and any damages repaired immediately.

Product Features

Some rotary tables have automatic or semi-automatic modes. Those machines usually have encoders, limiting switch sections, a motor driver, a control driver, a signal cable, and a power supply cable. They have two or more speeds. For example, a 57DT- rotational table has 2 driving modes - a planetary gearbox driven by a stepper motor and an AC synchronous servo motor. Speed is about 0.1°/s and 0.15°/s. Another example is the ZB(60)JK- rotary table. It has 4 driving modes with 2 speeds. The modes are an AC servo motor, DC servo motor, stepper motor, and permanent magnet DC motor.

Machinery Industry:

Rotary tables' workhorse part, the machining table, is a rotary table's centerpiece. Products on rotary tables may have any number of machining parts that rotate to achieve the goal of creating them. Machining cabinets, furniture, and other objects for the industry often make use of this rotary table workhorse.

Cake Decorating:

The food industry often requires decoration on cakes. A food rotary table can move cakes while decorators need to add icing, fondant, or other embellishments. One advantage of a cake decorating table with a rotating feature is that it allows for more precise and uniform decoration on the cake that is being decorated.

Assembly Lines:

A rotary table's assembly line function helps move and position parts in a way that is required for efficient assembly operations. Examples of this can be found in the automotive industry, electronics, and other industries. On assembly lines, the rotary table often provides the parts for assembly. Corner assemblies, however, include assembly operations that are more complex which require more complicated rotary tables, including those with CNC involvement. Rotary tables are great at facilitating rapid production and improving an assembly line's overall efficiency.

Jewelry Making:

The jewelry-making industry has artisans who make use of the precision of a jewelry rotary machine. Such machines help jewel-makers achieve intricate details and work when they're making jewelry pieces, like rings, earrings, necklaces, brooches, and bracelets.

CNC Machines:

Many shops make use of CNCs with a rotary table axis. This includes the workrooms of timber-whittling artisans. Woodworkers carve and engrave cylindrical objects like mantelpieces, columns, and other similar things made of wood, as well as tailored carpentry pieces. The woodworking CNC machine with a rotary table facilitates automated and accurate machining of such parts of the wood. A woodworking machine is great because it reduces the manual work required and improves precision and consistency.

Popular Science:

Popular scientists often use rotary tables to do experiments and rotate the apparatus during the reaction when required. Rotary tables allow chemical reactions to take place evenly. One common use for rotary tables in chemistry laboratories is for the rotary evaporator or rotavap, which removes solvents from chemicals by the means of heat. Another use could be in centrifuges, in which rotary motion is used to separate fluids and solids.

When shopping for rotary tables for sale, buyers should consider the following factors:

Q1: What factors should business buyers consider when selecting a rotary table machine for their specific needs?

A1: They should probably think about the type of work they do first – what materials they use and how heavy and big things are. Next, they need to decide on a machine that can handle the exact sizes and weights of the things they want to rotate. Pay attention to how precise and exact the rotary table is – more accuracy means better quality work. Also, consider how fast and strong the machine can move, as this affects efficiency. Make sure the rotary table can be easily connected and integrated with the existing machines they have, too.

Q2: Can rotary tables be used for materials other than metal?

A2: Yes, there are different types of rotary tables for different materials. While gear rotary tables are widely used in machining centers for metal processing, other rotary tables like the belt-driven one are suitable for more fragile materials like glass. This is because the tables can provide the right speed and precision needed for machining glass. So, regardless of the material – be it metal, glass, plastic, wood, or something else, there are rotary tables designed to work with all kinds of different materials.

Q3: How can businesses ensure the safety of their workers when using rotary table machines?

A3: Safety first! The rotary table machine should have proper guarding and shielding to protect workers from any moving parts. But, aside from that, make sure the workers are properly trained on how to safely operate the machine and also consider dumping the weight of workpieces being handled by the machine so neither the machine nor the operator has to handle extra. Moreover, carry out regular preventive maintenance on the machine and inspect it periodically to ensure that everything is functioning properly, and finally, establish safety protocols and procedures to avoid risk.