(624 products available)

A rotary table is a flexible work-holding component that allows for the rotation of items around a vertical or horizontal axis. There are two types of rotary tables: manual and CNC. Both types are available in different sizes and shapes to suit any requirement.

Manual rotary tables:

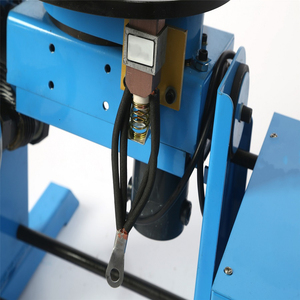

Manual rotary tables are tables that operators adjust manually to position the workpiece while doing machining operations. In this kind of rotary table, the machinist uses a hand crank to turn the worktable and expose other parts of the workpiece to cutters or other tools. Manual rotary tables are uncomplicated and cost-effective but require the operator to stop working to reposition the workpiece. Hand crank rotary tables are usually made with precise degree markings on the table so the operator can know how many degrees the table has turned for each turn of the crank.

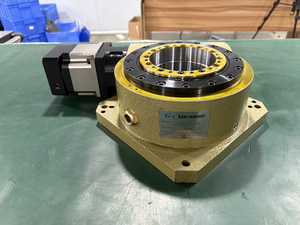

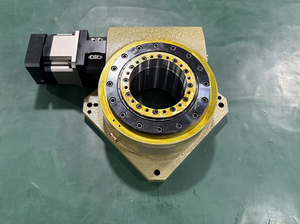

CNC rotary tables:

A CNC (computer numerical control) rotary table is a worktable fitted with an electrical motor that allows it to move automatically to position a workpiece during a machining operation. CNC rotary tables offer more accurate and efficient machining than manual tables and reduce the need for the operator to be present. An integral part of a CNC rotary table is a control program that tells the motor how far to turn the workpiece, and the degree of precision this allows is much greater than that achievable with a manual rotary table.

CNC rotary tables are usually very large and heavy and made of more massive metal parts than manual tables to cope with the increased precision and the workpieces' weights. CNC rotary tables are also more expensive than manual tables, and the operator must be more complicated and have advanced skills.

The specifications of a rotary table vary between models and types. Details such as the size, compatibility with different machines, and weight capacity are vital to consider when purchasing a rotary table.

Sizes

A rotary table with a table diameter of 100 mm is small and ideal for short vertical and horizontal workpieces. When coupled with a dividing head, it also helps to carry out projects that involve intricate circular cuts. However, larger diameter rotary tables like 300 mm can be used to support large diameter cylinders and discs.

Compatible Machines

The rotary table to choose will also depend on which machine it will be paired with. For instance, if a bench top drill is being used, an at- home rotary table would be a better fit than an industrial scale one.

Weight Capacity

All rotary tables have their work-holding capacities denoted. This capacity denotes the maximum weight the rotary table can support while rotating accurately. Small rotary tables generally support workpieces with a weight of up to 100 kg. Larger ones have higher capacities.

The simplest way to increase the longevity of a rotary table is to practice regular maintenance. This involves routine testing and monitoring of the table to see if any parts need repairs or replacements.

For its smooth operation over the years, cleaning it regularly should become a priority. Debris and dust build-up can severely hinder the performance of the table. Even a small amount of debris can cause it to jam or slow down temporarily. Regular cleaning ensures that no build-up occurs.

Lubrication is also vital to keeping a rotary table in a working condition for years to come. It minimizes any wear and tear from friction and keeps the functioning smooth and seamless.

While the above maintenance tips go a long way in enhancing a rotary table's longevity, it is always best to check with the manufacturer's manual for any specific requirements. Each table may call for distinct maintenance practices that should not be overlooked.

The 100 mm rotary table is an extremely versatile machine tool accessory used in various scenarios across metalworking and machining industries. Here are some of the most common application scenarios where the rotary tables are used.

With the demand for rotary tables increasing in the machinery market, it has become crucial to understand how to choose the proper machinery.

One should take into account the following factors:

Q: How accurate is a rotary table?

A rotary table is typically accurate to 1.5 seconds of arc or better, meaning it can position workpieces with a high degree of precision. Higher accuracy models are available.

Q: What are the challenges of rotary tables?

A few challenges are selection, as they may not suit all machining tasks; integration into existing CNC setups can be complex; and cost considerations as high precision, quality tables are expensive.

Q: Can rotary tables be used in CNC machines?

CNC machines often integrate rotary tables for more complex work such as shaping, drilling and milling at multiple angles. Custom-made tables are usually sought for this type of requirement.

Q: What castings are suitable for a rotary table?

The turntable and base are usually made from grey iron casting. For tables requiring high strength and rigidity, ductile iron castings are used instead. Discussing the specifics with the manufacturer is ideal to ensure suitable parts are chosen to meet requirements.