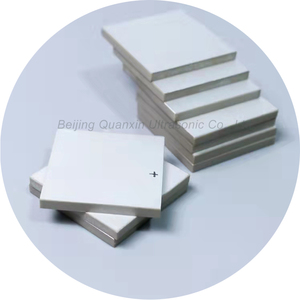

Introduction to Rectangular Piezo Elements

A rectangular piezo element is a specialized device that converts mechanical energy into electrical energy and vice versa, utilizing the piezoelectric effect. These elements are essential in various applications, from sensors to actuators, due to their reliable performance and compact design. Understanding the intricacies of rectangular piezo elements can help you leverage their full potential in your projects.

Types of Rectangular Piezo Elements

Rectangular piezo elements come in various forms to suit different applications. Here are some common types:

- Standard Rectangular Piezo Element: Commonly used in sensors and actuators, these elements provide flexibility and adaptability in various environments.

- Adhesive-mounted Rectangular Piezo Elements: These elements feature an adhesive backing that allows easy mounting onto surfaces, ideal for quick installations.

- High-frequency Rectangular Piezo Elements: Designed for applications requiring rapid response times, these elements work exceptionally well in ultrasonic devices.

- Custom-sized Rectangular Piezo Elements: Tailored elements that adapt to specific project requirements, ensuring optimal functionality.

Applications of Rectangular Piezo Elements

Rectangular piezo elements are widely utilized across various industries due to their versatility and efficiency. Here are some key applications:

- Sensors: Used in pressure sensors, accelerometers, and displacement sensors to measure mechanical changes.

- Actuators: Employed in precision control systems, robotics, and audio devices to convert electrical signals into precise mechanical movements.

- Ultrasonic Devices: Integral to ultrasonic cleaning machines, medical imaging equipment, and non-destructive testing tools.

- Energy Harvesting: Suitable for converting ambient vibrations into usable electrical energy to power small devices.

Features and Advantages of Rectangular Piezo Elements

Choosing rectangular piezo elements for your applications offers numerous features and advantages:

- High Efficiency: These elements provide efficient energy conversion, maximizing performance while minimizing losses.

- Compact Size: Their rectangular shape allows for easy integration into various devices without occupying excessive space.

- Wide Frequency Range: Capable of operating over a wide frequency range, making them suitable for diverse applications.

- Durable Material: Typically made from robust ceramic materials, they offer longevity and reliability under varying environmental conditions.

- Low Power Consumption: Ideal for energy-sensitive applications, reducing operational costs.

- Rapid Response Time: They can quickly respond to mechanical changes, making them perfect for high-speed applications.