Introduction to Piezo for Ultrasonic Atomizer

The piezo for ultrasonic atomizer is a cutting-edge component used to facilitate the conversion of electrical energy into high-frequency mechanical vibrations. This technology enables the efficient atomization of liquids into fine mist or aerosol, making it a pivotal element in various applications ranging from humidification to medical aerosols. Ultrasonic atomizers utilize piezoelectric materials to create ultrasonic waves, producing a consistent and fine mist that is essential for numerous industrial and consumer purposes.

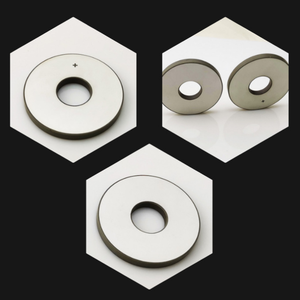

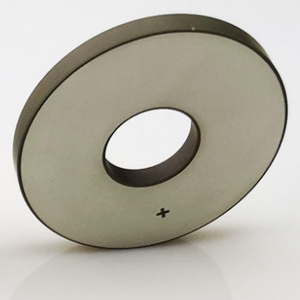

Types of Piezo for Ultrasonic Atomizer

When it comes to piezo for ultrasonic atomizers, various types are available to suit specific applications. Each type employs unique designs and materials to meet varying requirements:

- Ceramic Piezo Devices: Known for their durability and high-temperature resistance, these devices are commonly used in industrial atomizers.

- Composite Piezo Elements: These feature a combination of materials that enhance performance, particularly in providing higher displacement and efficiency.

- Thin Film Piezoelectric Sensors: Lightweight and compact, making them ideal for portable and consumer-grade ultrasonic atomizers.

- Multilayer Piezo Actuators: These devices are designed for applications requiring high output with very little power input, optimizing energy efficiency.

Applications of Piezo for Ultrasonic Atomizer

The piezo for ultrasonic atomizer has a diverse range of applications across multiple industries:

- Medical Applications: Used in nebulizers to deliver medication in aerosol form, making it easy for patients to inhale.

- Industrial Humidification: Effective in maintaining optimal humidity levels in production facilities, thus protecting sensitive equipment.

- Aromatherapy and Air Purification: Employed in diffusers to disperse essential oils into the air, enhancing indoor environments.

- Cosmetic Applications: Used in skin misting products and facial sprays for even distribution of liquids.

- Food Processing: Utilized in systems requiring precise application of flavoring or preservation chemicals in the form of a fine mist.

Advantages of Piezo for Ultrasonic Atomizer

The use of the piezo for ultrasonic atomizer comes with numerous advantages, making it a preferred choice for manufacturers and industries:

- Efficiency: Piezoelectric devices achieve high levels of efficiency, converting a significant amount of electrical energy into atomization.

- Compact Design: Their small size allows for integration into various devices without taking up too much space.

- Low Noise Operation: Unlike traditional misting methods, ultrasonic atomizers operate quietly, which is essential for both consumer and clinical environments.

- Uniform Droplet Size: The ultrasonic method produces a consistent mist with droplets of uniform size, essential for effective delivery and performance.

- Low Maintenance: Due to their robust design and lack of moving parts, piezoelectric atomizers require less maintenance compared to mechanical alternatives.