(45 products available)

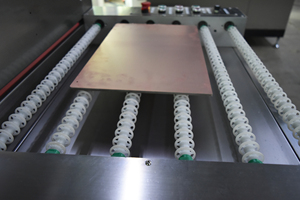

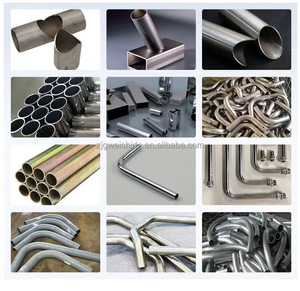

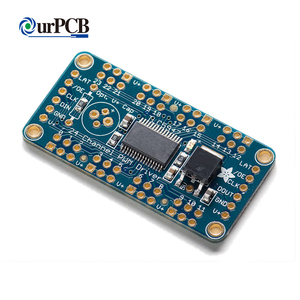

A PCB deburring machine is widely used in the electronics industry to remove burrs from printed circuit boards or other sharp edges, such as router bits. Different types of machines can be used in the manufacturing process.

These machines have many usage scenarios and applications in the industrial world.

Sharp edge removal

Exposed edges and sharp edges are typical scenarios where a deburring machine comes in handy. Sharp edges may result from cutting methods like laser cutting or water jet cutting. A PCB deburring machine will remove the exposed and sharp edges, making the product safer for handling.

Edge radiusing

A deburring machine will produce an ergonomic and comfortable edge radius on the PCB product. This creates a comfortable and a good fit on the customer's hand when using the product.

Without a deburring machine, the edges of a product can affect the overall quality. It can have an impact on the product's functionality and aesthetic appeal.

Edge finishing

A deburring machine can apply various edge finishes to a PCB product. This includes grinding, polishing, blasting, or coating. This puts the final touches on the product and improves its structural integrity.

Streamline assembly processes

When the edges of a product have burrs, it can negatively impact the assembly of the parts. A deburring machine will help simplify the process of assembly quickly and smoothly. Deburring also enhances the machining tolerances of the PCB products.

Repair and maintenance tasks

Deburring machines are very helpful in maintenance and repair tasks. Without a deburring machine, repairs will be very hard and complicated. The machines help to quickly and easily equip, repair, or service a PCB product.

As with any industrial machine, shopping for a PCB deburring machine requires an understanding of the features, specifications, and how they impact the production line.

Type of Machine:

Assess the board types and materials. Make sure the machine fits with the entire production line. Consider also the manual vs. automatic debate. While manual machines are more affordable, automatic ones improve productivity.

Operating System:

A user-friendly interface makes it easier for workers to learn the machine. Look for systems with clear instructions and wireless connectivity for remote management.

Production Capacity:

Choose a machine with the right capacity for supporting sales numbers. A small-scale machine will cost less but lead to missed revenue opportunities. On the flip side, a high-capacity machine may be an unnecessary expense if it produces more than the current needs.'

Processing Methods:

Select a machine with the right processing methods for current and future production. Vacuum suction is good for FPC, though sand blasting is a more popular choice. Water jets, ultrasonic cleaning, and laser removal are all advanced techniques worth considering if the operator can afford them.

Precision:

How accurate does the machine need to be for the current production requirements? Consider the balance between precision and cost. A precise machine with high accuracy will be more expensive, yet it may yield products that improve sales numbers.

Size and Weight:

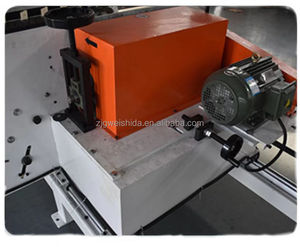

Can the machine fit well within the production area? Will it need extra costs for transportation or installation? A heavy, bulky machine may take longer to set up. Ensure the production line has sufficient space for the new machine.

Replacement Parts:

Over time, a PCB deburring machine will need replacement parts or upgrades. Assess the availability of spares and the cost of important components. Budget constraints may limit spending now, but it's still worth choosing a machine with good support for spare parts.

Warranty/Guarantee:

A warranty on the machine protects the buyer in case of defects or failures. Look for a solid guarantee that covers major defects for at least one year. Consider extra warranty coverage for certain parts, like the motor, which may wear out faster.

Q1: What are the types of PCB deburring machines?

A1: The types of PCB deburring machines include laser deburring machines, rotary burr deburring machines, PCB deburring machines with brushes, cryogenic deburring machines, and double-sided PCB deburring machines.

Q2: What is the process of a PCB deburring machine?

A2: The process of a PCB deburring machine involves placing the board into the machine, which applies pressure to remove the burrs. Besides, the boards can also be treated with chemicals followed by the brushing process. Finally, the board is cleaned.

Q3: What are the benefits of using a PCB deburring machine?

A3: The benefits of using a PCB deburring machine include improved electrical performance, enhanced mechanical properties, increased board longevity, and reduced assembly defects.