(236 products available)

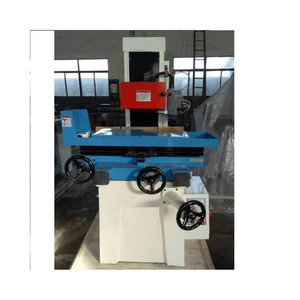

A manual surface grinder machine is a kind of surface grinder whose movement is operated by hand. The machine is used to grind flat surfaces on different workpieces. Generally, grinding is the process of removing small chips or parts from materials to create a smooth and level surface. The manual grinders are small and offer less precise work than automatic or semi-automatic surface grinders. Nonetheless, they are still essential tools in a workshop.

There are many types of used surface grinding machines for sale in the market. They can be divided into two primary categories based on control system and wheel movement.

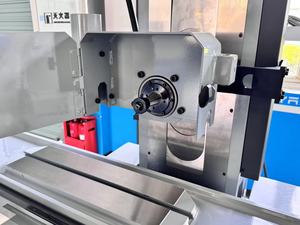

Users of the manual surface grinder will need to familiarize themselves with the grinding machine manual to understand its specifications. Below are some common specifications for surface grinders along with some general maintenance tips.

Manufacturers recommend users perform regular maintenance and cleaning services on their grinding machine parts. The maintenance services do not always require specialized skills, but user manuals may explain maintenance procedures in further detail.

Grinders with a lift table are useful when pairing with a milling machine. When milling, the workpiece height is transitioned to what is needed. Also, creating a better margin when doing edge and bevel work. This is vital when a workpiece needs to have features matched or approximated closely to another part.

Electrical parts and connectors need to be primed for a flawless weld. Surface grinders prepare a solder joint or weld by providing a cleaner contact area. This is more so when oxidization is an issue. Welding and soldering guns benefit from contacts that are flush and clean free of impurities.

Mounts, flanges, bases, and other items are irregularly shaped, which poses a challenge when trying to attach them to a workpiece. Surface grinders, especially those with magnetic mounts, provide a solid foundation to ensure uniform contact.

Surface grinders can repair tools like dies or punching tools. These suffer due to pestering from time and use and have indentations or rough areas that interfere with their task. Surface grinding creates a smoother, sharper, and more precise punching tool or die to improve the final product.

Tool edges and cutting surfaces can be honed to achieve greater precision and reduce the risk of error or accidents. Surface grinders allow the tools to be sharpened and maintained, which enhances productivity.

Corrosion can become a major enemy for metal parts to function optimally. A part that has scratches, gouges, or rough areas is at risk of becoming a host of corrosion. Surface grinding comes in and imprimes the part, reducing the area for corrosion to take root.

Exact specs on edges and surfaces are needed when connecting pieces of jigsaw puzzles. Surface grinders provide an exact specification when connecting two or more workpieces that are crucial to the strength and integrity of the entire structure.

Buyers should consider the following factors to select the right surface grinding machine.

Machine's Purpose

A manual surface grinder is suitable for general-purpose grinding tasks. It can handle multiple workpieces of varying shapes and sizes. The machine can also grind and level surfaces with different materials. Therefore, buyers looking for a machine to work on multiple projects should consider a manual surface grinder machine.

Operator's Skill Level

Unskilled operators may find it challenging to handle a manual surface grinding machine. In this case, the buyer should consider a machine with minimum manual control. Consider a machine with automated features or a simpler control system for partially-skilled operators. Conversely, fully automated surface grinders may not be suitable for skilled operators.

Machine Maintenance

Manual surface grinders need regular maintenance to function correctly and handle workpieces efficiently. The machine's maintenance needs will vary depending on the grinding tool's complexity. Machines with automated features and advanced technology will need specialist maintenance services. Buying surface grinders with frequently available spare parts is essential to simplify servicing and repair.

Production Volume

A manual surface grinding machine is suitable for low production volumes. The machine can efficiently handle around 50 workpieces daily. However, buyers should consider automatic and semi-automatic grinders for high-volume production, as the continuous operation of these machines maximizes efficiency.

Space Availability

Consider the manual grinder's footprint before purchasing. The machine will occupy space in the grinding workshop. Surface grinders come in large and small sizes. A manual surface grinder machine will be a suitable choice if the workshop space is limited. Alternatively, consider larger machines with greater capacities that can be accommodated in a spacious workshop.

Budget Constraints

Manual surface grinding machines cost less than automatic and semi-automatic machines. Nevertheless, the operator will likely manually feed the workpiece into the grinding wheel. This may take time and require extra manpower. Consider more automated grinding tools if the cost of manual labor is a concern.

Q1. How hard is it to operate a manual surface grinder?

A1. Operator training is necessary before surface grinders can be used.

Q2. Does a tight budget mean that it is better to use an old surface grinder?

A2. Surface grinders wear out and may not give acceptable results. It is better to purchase a surface grinder with a known history of usage and maintained surface grinders.

Q3. What are the templates in a surface grinder?

A3. Templates are the guides used to grind surfaces at specific angles.

Q4. What are the safety precautions when using a surface grinder?

A4. Safety precautions include wearing protective eyewear and operating the machine alone.