(1627 products available)

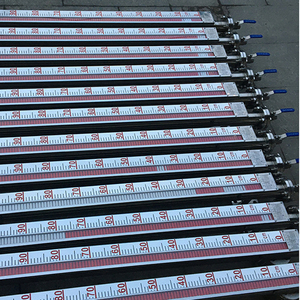

Level indicator floats work through different operating principles, and each type has its advantages depending on the characteristics of the measuring medium and the requirements of the application. Some of the most common types are:

Continuous measurement types

These provide an uninterrupted output of liquid levels within a reservoir or tank. They are primarily used where precise measurement is necessary. Operational examples include radar and magnetic level indicators.

Point measurement types

Only detect levels at specific points are adequate for on/off control applications or point level detection. Common point measurement types include float switches and capacitive level sensors.

Mechanical and non-mechanical classes

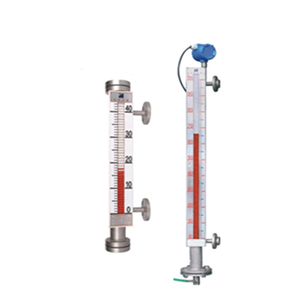

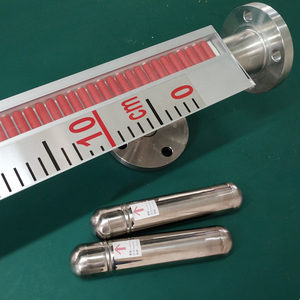

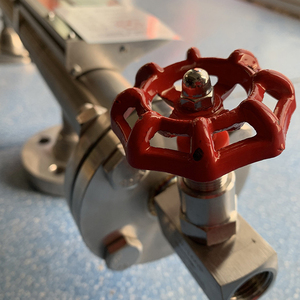

Another categorization of level indicators is based on their operating technology – mechanical floats linked to the gauge glass via levers or chains, providing a visual reading, whereas non-mechanical indicators like radar, ultrasonic, or pressure transducers work without direct contact with the fluid, offering diverse industrial-fitting needs and safety requirements.

Chemical industry

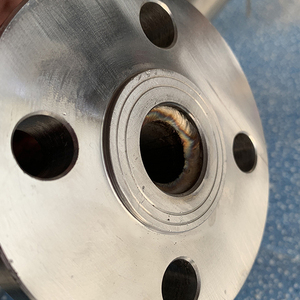

In chemical processing plants, these indicator floats are essential for measuring and controlling the level of various chemicals in reactors, storage tanks, and vessels. They help ensure safety by preventing overflows or dry runs in critical equipment. Depending on the float materials and design, these level indicators withstand corrosive substances, making them ideal for use in such harsh environments.

Oil and gas industry

Used in refineries, oil rigs, and storage facilities to measure liquid levels in tanks, separators, and pipelines. The float level gauge are crucial for monitoring product levels, maintaining safety standards, and optimizing operational efficiency. They give reliable readings in extreme conditions like high pressures and temperatures.

Food and beverage industry

Float indicators measure and control liquid levels in brewing, fermentation, and storage tanks, ensuring consistent product quality. In dairy, these floats handle varying liquid densities and temperatures. They are critical in delivering precise and dependable measurements for effective production processes.

Pharmaceutical industry

Used in the drug manufacturing process to maintain levels in mixing, storage, and filtration vessels. They need to fulfil strict cleanliness and accuracy standards. The right level measurement solution – whether contact or non-contact – guarantees precise formulation, reduces waste, and assures regulatory compliance.

Water and wastewater treatment

Indicator floats monitor levels in tanks, clarifiers, and digesters, automating pump control and ensuring efficient treatment processes. They are vital in managing water levels and quality in municipal and industrial treatment facilities. Float types measure sludge, scum, and liquid levels, enabling proper flow management and treatment sequence adherence.

Some of the common float type level indicators include:

When buying, consider these factors:

Application and environment

Indicator floats hold and work with liquids that are easy to identify. In food and chemicals, get smooth floats that touch the stuff. For water storage, choose simple switches and cylinders. Radar and ultrasonic types work in rough spots.

Level of accuracy

For accurate readings, use radar or magnetic types. Floating switches, though less exact, are good for basic tasks.

Cost

Switches and cylinders with simple mechanical floats are cheap at first. Magnetic, radar, and ultrasonic ones cost more upfront but save in power use and fewer breakdowns.

Requirement for maintenance

Indicate floats with no moving parts, like radar, need less care. Switches and mechanical floats need more regular checks.

Material

The float's makeup matters. Plastics work on food. Stainless steel suits chemicals. Every type provides safety.

A1: These level gauges let one know how much liquid or solid is inside something, like a tank or barrel. They give a clear, simple look at the levels, unlike other tools that are harder to read. They are easy to set up and cost less than some high-tech choices. Unlike some sensors, they work well with all kinds of materials. Even in tough places, like extreme heat or pressure, they can keep going strong.

A2: Level floats are inexpensive and reliable, making them easy to use regularly. Unlike other options, they don't need power to work. They are well-made to take shocks. In factories and storage, these simple tools help keep things running smoothly without complex electronics.

A3: They can get stuck and give false low readings. If dirty or full of foam, they miss the mark by a wide margin. Some types need power or get in the liquid, which might not suit all tasks.

A4: Most last about 15 years if cared for. Clean them often, and avoid extreme heat or pressure to keep them working. With minimal wear and tear, they can keep going long past their expected years of service.