Understanding Inputs and Outputs PLC

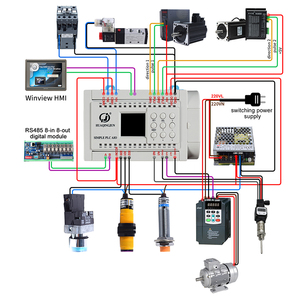

The realm of automation is significantly driven by Programmable Logic Controllers (PLCs), which serve as the backbone for various manufacturing processes and operations. At the core of every PLC system lies its inputs and outputs. These inputs and outputs PLC configurations are crucial for monitoring, controlling, and optimizing industrial processes by interfacing with the physical world and enabling real-time processing of data. Let’s dive deeper into the types, functions, features, and applications of inputs and outputs PLC systems.

Types of Inputs and Outputs PLC

Inputs and outputs in a PLC system can be categorized based on their nature and function. Understanding these types can significantly enhance the efficiency of your automation system.

- Digital Inputs: These inputs receive signals that represent two states - on and off, typically from devices like push buttons or limit switches.

- Analog Inputs: Analog inputs measure and monitor varying signals, such as temperature or pressure, providing more nuanced data compared to digital inputs.

- Digital Outputs: These outputs send signals to control devices, like motors or relays, switching them on or off.

- Analog Outputs: These outputs control the level of a variable continuously, allowing for sophisticated automation of processes, such as modulating a control valve.

Function and Feature of Inputs and Outputs PLC

The functionality of inputs and outputs PLC is essential for seamless industrial automation. The following features enhance their effectiveness:

- Real-time Data Processing: PLCs can process data from inputs and outputs in real-time, enabling immediate responses to changing conditions.

- Scalability: Inputs and outputs PLC systems can be easily expanded by adding more modules or devices, offering flexibility for future modifications.

- Integration Capability: These PLC systems can integrate with various sensors and actuators, creating a cohesive automation solution.

- User-friendly Programming: Most PLCs come with accessible programming software that simplifies the customization of input and output operations.

- Robust Performance: PLC inputs and outputs are designed to withstand harsh industrial environments, ensuring reliability and longevity.

Applications of Inputs and Outputs PLC

Inputs and outputs PLC systems have widespread applications across various industries due to their versatility. Some significant applications include:

- Manufacturing Automation: Used extensively to control machine tools, assembly lines, and robotic process automation.

- Home Automation: In smart homes, PLC systems can manage lighting, heating, and security systems with inputs from sensors.

- Water Treatment Plants: Inputs from water quality sensors help manage treatment processes for safe drinking water.

- Food Processing Industries: Inputs and outputs PLC systems manage the production lines and control packaging processes efficiently.

- Automotive Industry: In automotive production, these systems control assembly lines, ensuring precision and quality in manufacturing.

Advantages of Inputs and Outputs PLC

There are several advantages to utilizing inputs and outputs PLC in your automation processes, making them the preferred choice for many industries:

- Enhanced Control: PLCs offer granular control over automated processes, leading to improved quality and performance.

- Increased Efficiency: By processing data in real-time, PLCs can optimize operations and reduce downtime.

- Cost-effectiveness: Investing in a PLC system can lead to significant long-term savings due to increased operational efficiency.

- Reduced Maintenance: Robust PLC components require less maintenance, allowing you to focus resources on critical areas of your business.

- Improved Safety: By automating processes and providing precise control, inputs and outputs PLC assist in creating a safer working environment.