(502 products available)

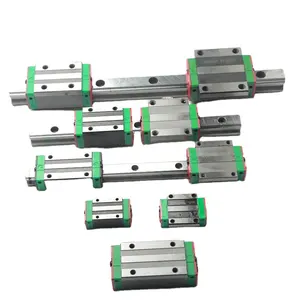

HG: This carriage contains four block slider models. The four-block carriage provides excellent load capability, stiffness, and stability. The four-block design allows loads to be distributed across two additional slider rails, resulting in a more rigid and stable slider for high-capacity applications. For this reason, they are typically used in high-load and demanding scenarios like CNC machines, large-scale automation equipment, and industrial robotics.

Using MGN9C linear rails, the MGC carriages contain a mini-sized carriage with no extra space. Therefore, they occupy less area than other carriages. These linear slide rails are perfect for compact and light systems. Besides, they provide load capabilities, stiffness, and stability, such as their counterparts. Usually, they are commonly used in 3D printers, small-scale automation systems, and lightweight robotics where space is limited but smooth motion is essential.

P-G: This is a public carriage that includes a shaft with an open end. The open-ended design allows easy access to the internal components and great customization, maintenance, and assembly. Additionally, the easy access to the block and linear rail makes the P-G carriage easier to set up and replace. Because of this, they are typically used in educational settings, maker spaces, and rapid prototyping where frequent assembly and disassembly are required, and customization is essential.

The MGN rail guide's M9C specifications indicate its dimensions. The table below depicts some of its critical components and dimensions.

| Component | Dimension/Description |

|---|---|

| HIWIN MGN9C length | 400mm to 1500mm≤Length≤1500mm |

| Height | 8.7 mm |

| Weight | 0.335Kg |

| Overall width | 9 mm |

| Width between mounting holes | Length ranges from 36 to 65.5 (for 400 mm length, it is 36 mm; for 600mm it is 46.6mm; for 800mm 56.6mm) |

| Width of rail | 8.9 mm |

Regular maintenance can extend the lifespan of an M9C linear guide. Here are some linear guides maintenance tips:

Industrial Automation

HIWIN linear guides are crucial in the automation field. They are applied in robots, assembling lines, and packing machines. The guides render motion precisely and reliably, meeting the large demands of productivity.

Machine Tools

HIWIN linear rails are widely used in CNC machines and lathes as a motion control component, assisting machines in accomplishing tasks like cutting, milling, and engraving with a high level of accuracy and consistency.

Medical Equipment

The medical equipment industry calls for high-precision instruments. The medical equipment industry, including MRI machines and oxygen generators, utilizes linear guide rails of great precision and stability.

3D Printing

In 3D printing machines, MGN linear rails support the print head or platform to realize the movement in different axes. With reliable stability, the guide rails ensure the print models' quality and precision.

Optical Devices

In optical devices, such as laser cutting machines, linear guide rails provide stable and precise motion for lasers or workpieces, ensuring accurate and high-quality cuts.

Aerospace Applications

In the aerospace field, HIWIN linear guides help with the assembly and inspection of aircraft components. The HIWIN guides are able to ensure the precise position control and repeatability of aerospace instruments and satellites, such as satellite launch pads and aerospace test stands.

Electronics Manufacturing

Electronics production lines also apply linear guide rails. Linear guide rails assist in the handling, insertion, and testing of electronic products like PCBs.

When choosing HIWIN linear guides for a specific application, several factors must be considered to ensure that the selected guide will meet the movement requirements.

Load capacity

The expected load, including weight, static and dynamic loads, and any additional forces (e.g., wind or acceleration) acting on the moving element, must be considered when calculating the load capacity. To prevent overloading and ensure a safety margin, it is necessary to understand the distribution of the load and the guide's operating environment.

Environmental factors

Factors such as temperature, humidity, dust or debris, exposure to chemicals or liquids, and vacuum or pressure conditions should be considered. For example, when working in a high or low-temperature environment, a temperature-resistant linear guide rail may be required. In contrast, a linear guide with enhanced sealing or lubrication system may be selected for dusty or contaminated environments.

Length and accuracy

The travel length of the guide must be sufficient to accommodate the desired stroke. The required positioning accuracy and repeatability also need to be considered. The linear guide must provide the necessary precision to achieve the desired mechanical system performance.

Cost considerations

The budget for the application must be considered, as the selection of the linear guide will affect the overall cost of the system. Cost is a crucial consideration, but it should not come at the expense of performance and reliability.

Q1: Can users find other MGN linear guides in the Hiwin catalog?

A1: The Hiwin MGN linear guide has a modular design that makes it easy to manufacture different sizes by changing certain features. Aside from the MGN9, other available sizes include the MGN15, MGN12, MGN16, and MGN20 rails.

Q2: What material does the Hiwin linear guide rail car block use?

A2: The car body is usually made of aluminum alloy to provide strength. However, for more demanding applications, users can select a steel option.

Q3: Does the Hiwin linear guide have a self-lubricating option?

A3: Yes, aside from the standard lubrication system, the MGN guide offers a self-lubricating option. It incorporates a graphite-based solid lubricant that reduces friction between the block and rail.

Q4: What is the difference between linear guides and traditional machine bearings?

A4: Linear guides permit direct linear motion, whereas traditional machine bearings only allow for rotary motion. Linear guides take high radial loads in a single direction and provide additional load capacities.

Q5: How simple is it to replace a linear guide in a machine?

A5: The block and rail are usually mounted using machine bolts, making it simple to replace them. However, it is important to inspect and ensure the parts' alignment after replacement.