(1495 products available)

As essential implements in the farming industry, hay rakes for tractors come in diverse types to meet various agricultural needs. The following table summarizes some of them:

Rotary Hay Rakes:

Primarily designed for larger-scale operations, tractor-mounted rotary hay rakes are popular for efficiently managing windrows of hay or straw. They usually have a curved arm with tines that rotate to lift and fluff the grass. One main feature of a rotary hay rake is its ability to control the density and quality of the forage. This makes it a preferred choice for those looking to produce high-quality hay. Furthermore, many models boast a smooth, clean operation thanks to their individual wheels pneumatic tires that each have separately mounted tines. Another interesting thing about rotary hay rakes for tractors is that they make less noise and produce less dust than others.

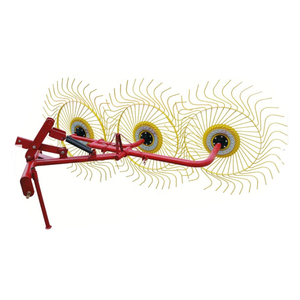

Finger Wheel Rakes:

Also known as semi-mounted rotary hay rakes, this type of tractor hay rake features a number of wheels with spring-loaded fingers. Each wheel usually has a set of ''fingers'' attached to its hubs which gently lift and flip the grass. Farm owners frequently rake hay with finger wheel rakes, as they are pulled behind the tractor and attached to the three-point hitch. Additionally, they are easy to use and offer good maneuverability in the field. Another reason this type of hay rake is so popular is their relatively low cost compared to other models. It is worth noting that finger wheel rakes tend to leave some debris behind after the job is done. This may not be a big deal to most users yet should be considered, especially when using it for quality hay production.

Disc Hay Rakes:

Disc hay rakes for tractors are a more recent innovation in the field of hay raking. They make use of several smaller discs to rake the hay into windrows. This type of hay rake can be pulled with a tractor or mounted on it. Similar to rotary rakes, disc hay rakes operate with rotating discs. Each disc has a number of tines attached to it. Those tines grab the forage and flip it over. One of the greatest features of disc hay rakes is their versatility. They handle a wide variety of forage types and conditions. Plus, they are very efficient at raking dry and damp hay. On the downside, disc hay rakes for tractors are often more expensive than many of their counterparts. Furthermore, their maintenance costs can be on the high side.

Hay rakes for tractors come with a variety of specifications to suit different farming needs. The width of the raked area is an important specification. Generally, the width raked by a hay rake for tractor ranges from about 2 meters to 7 meters. Larger widths are found in wider models.

The number of rake arms or tines on a tractor hay rake varies from model to model. Typically, there are about 6 to 14 arms on the rake. Sometimes, the arms are grouped together in sets called ‘clusters’. Here, they are referred to as ‘lower gears,’ and there are usually 3 lower gears. The upper gears, which are also called clusters, refer to the upper settings of the tractor hay rake. It is possible to find 4 upper gears on the rake. Gears are usually attached to a vertical shaft that connects to the main horizontal shaft of the rake.

The amount of hay raked in one go depends on the width and number of arms or tines on the rake. Generally, the larger the width and the more arms there are, the greater the quantity of hay raked.

Another key specification of a hay rake is its operating speed. Most hay rakes work at an ideal speed of 8 to 12 miles per hour. This speed helps the machine to reach maximum efficiency while reducing any damage to the crop.

Several maintenance parts of a hay rake need to be attended to on a regular basis. These include grease fittings, bearings, and pivot points. Continuous lubrication is necessary for the smooth functioning of the tractor hay rakes. Most of the grease fittings are easy to locate and access. Many rake manufacturers provide detailed instructions on specific lubrication points and recommended grease intervals.

Checking and replacing belts is an important part of tractor maintenance. One needs to conduct periodic inspections to ascertain the condition of the belts. At the same time, one should also look for and address any adjustments required on the hay rake.

Usually, special maintenance requirements are found only in specific models. But generally, one needs to ensure that the machine is free of any debris or dirt. In this case, the cleaning of the rake with compressed air helps a great deal. After all, dirt accumulation can negatively impact the equipment's performance and function.

To ensure the longevity of a hay rake for a tractor, it is required to store it in a well-controlled environment. The storage area for the equipment should be dry and clean. Furthermore, it should be protected from any hazardous environmental elements that can affect the machine.

Hay rakes present numerous applications for farmers and their livestock. The primary purpose of this rake is to create windrows of hay after mowing. These windrows will facilitate hay drying. Furthermore, the hay rake will gather the scattered dried grass into rows for easy harvesting using a baler machine. The use of the hay rake reduces wastage of dried grass that can be used for grazing or livestock feeding.

Rotary rakes can adjust to different types of grass and soil. It can be used on uneven terrain without causing damage to the grass or soil. Therefore, they are suitable for every terrain. Additionally, the hay rake can be used to collect leaves, straw, and other debris on the farm. The gathered leaves can be composted or mulched. Raked debris also clears the farm for easier crop cultivation and better yield.

The hay rake for a tractor is not limited to farm use. The tool can be used to gather leaves or grass in the yard into a manageable portion for uprooting. Furthermore, the machine can be employed to level the yard after moving or destruction by sporting activities or extreme weather conditions. Use the hay rake to spread the topsoil and create an even surface. The practice will reduce the chances of soil erosion and promote even water and nutrient distribution upon gardening or farming.

A tractor-mounted hay rake, also called a tractor raked hay, is the most commonly used hay rake. This type of rake is attached to the three-point hitch system of a tractor and rakes out the hay that has been matted down by the weight of the moisture and earth underneath it. Because the tractor pulls it from behind, the operator has more control over the rake and can use a larger rake head area.

In the case of a rotary rake, consider whether the gear-driven system would be preferable to a chain-driven one. A gear-driven system is more efficient, while a chain-driven system is easier to maintain and repair.

Gear-driven system: Gear-driven driven systems have better operational efficiency. Power transfer occurs through a series of gears, driving the rotating wheels. They offer precise control over wheel speed, allowing consistent raking results. Gear-driven rake wheels run at higher speeds than chain-driven wheels, resulting in more extensive areas being covered in less time. This efficiency is especially beneficial for farms where hay is fundamental to the annual income and needs to be harvested quickly and efficiently.

Coverage area: A wide-angle hay rake has a coverage area of around 30 to 50 feet and is well-suited for large farms raking hay on vast acreage and where raking large swathes of hay is necessary. Normal coverage areas would include those where raking on around 20 to 30 acres in one area is possible. Normal or standard areas of coverage are anywhere from 15 to 20 feet.

A medium rake would have a coverage area of around 10 to 15 feet and would be used for small to medium-sized farms or ranches where raking on smaller acreage is necessary. In some cases, smaller areas might be difficult to cover with larger rakes, making it more efficient to use a rake with a small coverage area.

Q1: How fast should a tractor hay rake go?

A1: Around 5-7 mph is generally accepted as an effective speed for raking hay. This allows the tractor driver hay to have enough time to perform its functions without damaging the hay.

Q2: What is the difference between a hay rake and a hay tedder?

A2: A hay rake gathers and organizes hay into serps for drying, whereas a hay tedder spreads out freshly mown grass to facilitate drying. Moreover, a hay rake operates in a backward motion, while a hay tedder moves forward.

Q3: How much HP does a hay rake need?

A3: Generally, 20 to 25 horsepower is sufficient to operate a small or medium-sized tractor-mounted hay rake. However, larger models may require more power.

Q4: Are rotary rakes better than wheel rakes?

A4: Rotary hay rakes for tractors are better for speeding up the raking process. However, they can be more expensive and require more maintenance. Wheel rakes are more affordable and easier to maintain, but they are better bpy faster spped.