(287 products available)

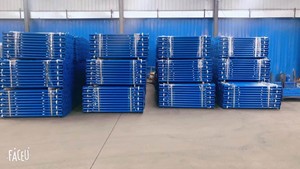

A formwork shoring screw jack is a device that helps construction workers support temporary structures. It's essential for safely and efficiently supporting beams, slabs, and columns during construction. Screw jacks are vital in formwork as they transfer the weight of the concrete to the ground, providing stability and safety until the permanent structure is in place.

Formwork screw jacks are made up of three parts: the outer tube, which is welded to the plate and bears all the loads; the inner tube moves up and down through the outer tube; and the third part is the screw, which turns and pushes the inner tube up or down.

There are different types of formwork shoring screw jacks, including;

Adjustable steel prop: This is a load-bearing device used in formwork to support vertical structures like beams and slabs. They are cost-effective and economical because they can be reused multiple times on different construction sites. They are also easy to install and require minimal maintenance.

Acrow jack: These screw jacks provide support and stabilization to structural applications in construction. They are versatile and can be adjusted to fit different heights and load capacities. Acrow jacks are lightweight, making them easy to transport and install. They are also made from high-strength steel, which improves durability and longevity.

Shoring steel jack post: These are vertical posts used to support and stabilize the load in construction, especially when the load-bearing walls are removed. They are made of high-strength steel, which provides maximum stability and support. Steel jack post are adjustable, allowing them to be adjusted to fit different heights and load capacities.

Props: These are devices used to support formwork in construction for horizontal structures like concrete slabs and beams. They are made of steel or aluminum and are adjustable to fit different heights and widths of formwork. They are also lightweight and easy to handle, making installation and removal efficient.

Screw jacks for shoring have various applications in construction. Their forms and features include:

Formwork Screw Jack

These screw jacks are used to temporarily support vertical formwork during concrete pouring and setting. They ensure that the formwork remains stable and aligned, producing concrete structures with accurate dimensions. They are also known as construction screw jacks.

Shoring Screw Jack

Shoring screw jacks provide adjustable support to structural elements like beams, columns, and walls. They are used in shoring to support and stabilize existing structures during demolition or renovation. These jack screw for formwork support provide load-bearing capacity and enhanced stability to shoring structures.

Height Adjustment

Formwork and shoring screw jacks provide height adjustments. They have a telescopic design with multiple extending sections. These sections can be adjusted manually or by using an electric screw jack to increase or decrease their height. This allows precise height adjustments to accommodate different construction requirements and terrain variations.

Load Bearing Capacity

These jacks have high-strength construction materials, such as steel. They are designed to withstand significant loads. Structural analysis and testing are usually performed to ensure that these jacks can safely support the required loads. The load-bearing capacity is usually indicated and can range from a few tons to several tons.

Easy Installation and Removal

Formwork and shoring screw jacks are easy to install. They are equipped with a top mounting plate or flange that allows easy attachment to formwork or shoring systems. These jacks are also easy to remove after the construction process is complete.

Durability and Corrosion Resistance

These jacks are made of durable materials. They are exposed to harsh conditions, and they are designed to withstand wear and tear. Formwork and shoring screw jacks are equipped with protective coatings, such as galvanization or powder coating. This provides resistance to corrosion and increases their lifespan.

Versatility

These jacks can be used in different applications. They support various formwork systems, including metal, timber, and composite formwork. Formwork and shoring screw jacks are suitable for different construction projects, ranging from residential buildings to high-rise structures and infrastructure projects.

Formwork shoring screw jacks have wide applications in construction. Their primary purpose is to support formwork and structural components during construction. Let's explore their usage across various industries.

Construction Industry

These jacks are used to support concrete formwork in pouring slabs, beams, and walls. They ensure stability and alignment of formwork prior to concrete setting. Additionally, they provide temporary support to structural elements like beams, slabs, and columns during construction. This allows for safe work practices and continuous construction cycles.

Bridge Construction

Shoring screw jacks are used to support bridge formwork and falsework. They ensure proper alignment and stability of formwork until concrete cures. This allows for the construction of safe and durable bridges.

High-Rise Building Construction

In the construction of tall buildings, these jacks offer multi-level shore support systems. This distributes loads uniformly and provides enhanced stability. Additionally, they support climbing formwork systems. This facilitates the rapid and safe construction of high-rise concrete structures such as core walls and columns.

Infrastructure Projects

Formwork shoring jack screws support large-scale infrastructure projects such as dams, parking garages and retaining walls. They ensure the structural integrity of massive concrete structures during curing. Additionally, they provide temporary shoring support to existing walls and structures during excavation and construction.

Industrial Construction

These jacks are used to support heavy-duty formwork for the construction of industrial facilities. This includes warehouses, factories, and power plants. They allow for the construction of large clear-span structures with high ceilings.

Precast Concrete Installation

Shoring screw jacks temporarily support precast concrete elements such as beams, girders, and slabs during installation. This ensures precise positioning and alignment before permanent connections are made.

Renovation and Retrofitting Projects

These jacks can be used to provide temporary support to existing structures. This includes beams and columns during renovations. They also can be used to support new structural elements being integrated into existing construction during retrofitting.

There are several factors that need to be considered when buying shoring jack for sale. The factors include;

Load capacity

When choosing screw jacks for formwork, it is important to consider the load capacity. This is the amount of load the jack can support. The load capacity needs to be matched with the structural requirements of the project being undertaken. Each construction project has its own unique requirements.

Height adjustment

Height adjustment is an important factor to consider when choosing a construction screw jack. This is because construction screw jacks are used for supporting structures. Therefore, the height adjustment feature allows the screw jack to be adjusted to different heights. This makes them suitable for various applications in construction.

Material and durability

Construction screw jacks are constructed using different materials. Some of the common materials used include; high-strength steel, galvanized steel and aluminum. The materials are constructed to be durable. This means that they are able to withstand harsh conditions and also resist corrosion.

Compatibility

Compatibility is an important factor when choosing construction support jacks. This is because compatibility determines whether the screw jack will work as intended. It is important to ensure that the screw jacks are compatible with the formwork system that is being used.

Ease of use and installation

Installation and ease of use are important factors to consider when choosing any formwork jack. This is because ease of use and proper installation will allow the jacks to function properly. Proper installation also ensures that they are safe. This is because poorly installed jacks can lead to accidents or injuries.

Q1: Can these jacks be used in all weather conditions?

A1: Yes, the jacks can be used in all weather conditions. However, hot-dip galvanization is recommended to enhance the screw jack's durability against corrosion.

Q2: What is the maximum load a formwork shoring screw jack can support?

A2: The maximum load depends on the size and material of the jack. For instance, a 3.5m adjustable prop can support a load of up to 22000N (22KN), while a 4m prop can support up to 25000N (25KN). However, it is advisable to consult an engineer to determine the appropriate prop according to the project's requirements.

Q3: How to maintain formwork shoring screw jacks?

A3: The jacks are maintained by regularly inspecting them for any damage or wear, cleaning them to remove any dirt or debris, and lubricating the threads to ensure smooth operation. It is also important to store them properly when not in use.

Q4: Are these jacks reusable?

A4: Yes, formwork shoring screw jacks are reusable. They can be used for multiple construction projects, making them a cost-effective solution for supporting formwork and structures during construction.

Q5: What are the common materials used in constructing formwork shoring screw jacks?

A5: The common materials include high-strength steel, which is durable and able to withstand heavy loads, and galvanized steel, which offers excellent corrosion protection. Aluminum is another common material, and it is lightweight and easy to handle.