(1113 products available)

Emulsion printing ink has several varieties. Each type has particular features that serve particular materials and tasks. Below are the standard types of these inks:

Acrylic Emulsion Inks

Acrylic emulsion inks contain color pigments inside an acrylic polymer emulsion base. These inks, which are water-resistant, take UV light well. Because of this, they are applicable for use on paper, fabric, and plastic. These inks are commonly used for offset and screen printing. These provide flexibility and a broad range of adhesion.

Latex Emulsion Inks

Latex emulsion inks are distinguished from other water-based inks by their latex polymer binders. These inks are ideal for wide-format printing on vinyl and other substrates. They come with added flexibility and durability. Latex inks offer a more ecological approach than solvent inks. This is because it does not use solvents but rather utilizes emulsions as the basis.

Plastisol Inks

However, plastisol inks normally comprise PVC particles suspended in a PVC solvent. Plastisol inks are classified as a type of emulsion printing ink. Plastisol inks are primarily used in textile printing, particularly on T-shirts. Plastisol inks are heat-cured to achieve a level of washing and fading durability.

Emulsion Polymerization Inks

These inks are produced through emulsion polymerization. With these inks, monomers are polymerized in an emulsion system containing water and surfactants. Emulsion polymerization refers to the process of making polymers via emulsion. These inks provide several benefits, such as resistance to chemicals and flexibility. Due to this, they are suitable for a wide range of substrates, including metal and glass.

Hybrid Inks

Hybrid inks are partially made up of traditional ink ingredients and modern emulsion ink ingredients. These inks can cure through heat or light, depending on the formulation. They offer flexibility in printing processes. Hybrid inks also help reduce emissions of volatile organic compounds (VOCs).

Quick Drying Speed

Emulsion printing inks have a fast drying rate. The inks dry partially, even fully drying as the printed material passes through a dryer. Some inks quickly dry upon being exposed to heat or UV light. Quick drying makes it possible for printers to print many copies quickly.

High Adhesion

Emulsion inks are designed to stick well to several surfaces. This is particularly true for hard-to-print surfaces like plastic and metal. The formulation of these inks includes finer pigments and resins. They enhance the inks' ability to adhere. This property guarantees a brilliant color surface that is more robust and fades less.

Flexibility

Once cured, emulsion inks turn flexible. That means they can bend and stretch without cracking or peeling. This property is particularly advantageous for printing on fabrics and other flexible materials. These inks will maintain the printed design's integrity even in the material's reshaping.

Environmental Safety

Water-based emulsion inks are a safer alternative to oil-based inks. Most emulsion printing inks are water-based, which makes them reduce VOC emissions. Volatile Organic Compounds (VOCs) are a major ecological concern and an area of human health concern. These features, along with incorporating less hazardous substances, make these inks more suitable for printing in packaging and other products meant for personal use.

Versatility

Available in many formulations, emulsion inks can suit various printing techniques. Unique applications of these inks include screen printing, offset printing, and digital printing. These inks are effective for diverse uses, whether the substrate is fabric, paper, or plastic. Such versatility makes it easier to select the right ink for any task.

Due to its versatility and a wide range of benefits, this ink is used in many different ways. Below are the printing processes that utilize these inks:

Digital Printing

These inks are becoming a more favorable choice in digital printing. This is particularly true for large-format printing. Their formulation allows for the precise application of ink onto various substrates. Substrates like vinyl, canvas, and photo paper particularly suit these inks. These inks also help reduce the emission of volatile organic compounds (VOCs) compared to solvent-based inks. This makes them especially advantageous for environmentally-conscious printing businesses.

Screen Printing

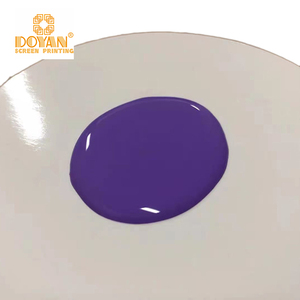

These inks are widely applied in screen printing, especially in textile printing. This is for printing designs onto T-shirts and other garments. Plastisol and water-based inks are the most common types of emulsion printing ink used here. Plastisol inks have PVC particles suspended in a gel-like liquid. It creates a thick, durable design that withstands washing and sunlight exposure on fabrics. Water-based emulsion printing inks, on the other hand, penetrate the fibers of the fabric. They leave a soft feel that is eco-friendlier and more suitable for use on color fabrics.

Offset Printing

Offset printing commonly employs emulsion inks. In this printing type, these inks deliver high-quality, sharp images and clear text, especially on paper and cardboard. The inks used in this printing method provide great color fidelity and a broad range of coverage. This makes them match well with commercial printing needs like brochures, business cards, and packaging.

Packaging Industry

Manufacturers in the packaging sector primarily use emulsion inks. These inks are suited for printed materials like boxes and labels. Their adherence to varying substrates (e.g., plastic, cardboard) makes them valuable for this application. Their resistance to chemicals and moisture ensures that the printed designs are durable. This is true even as the packages undergo handling, transportation, or storage.

Industrial Printing

Industrious printing types like circuit boards and metal coatings also make use of these inks. For these applications, the flexibility and adhesion of emulsion inks are very advantageous. The inks can adhere smoothly to irregular surfaces to be robust and functional. These features further offer protection against environmental factors like water and extreme temperatures.

Compatibility with Substrates

To fulfill a particular task, one must first consider the substrate they intend to print onto. Be it paper, plastic, or fabric, one has to choose emulsion printing inks that adhere well to these materials. Checking the manufacturer's specifications guarantees that one will pick ink compatible with their substrate. Further research may also help find emulsion inks that enhance the texture or appearance of specific substrates.

Ink Formulation

Emulsion inks for printing possess distinct formulations that deem them ideal for particular applications. For instance, textile printing demands more durability and flexibility. Plastisol inks would be most ideal in this case. Offset and digital printing, however, are better served by water-based or acrylic emulsion inks. These inks ensure an easier flow and enhanced adhesion to paper.

Drying Time

Drying time is an important factor to consider when selecting emulsion printing ink. If it is a high-speed printing task, look for inks with quick drying times. These include latex and UV-cured inks. On the other hand, if it’s not a fast-paced job, one can go for slower-drying inks. These would be water-based inks that are easier to handle and won’t dry out too fast during use.

Environmental Considerations

One can select eco-friendly emulsion inks if ecological factors are top priorities. Such inks have low VOC content. This makes them an ideal choice for businesses that aim to reduce their carbon footprints. Furthermore, these kinds of inks use water rather than petroleum solvents for their formulation. This makes them safer for both environmental and occupational health.

Color Quality and Fidelity

It is important to consider the color quality and fidelity of emulsion printing ink. Some inks have better color rendering and a wider color gamut than others. For instance, acrylic emulsion inks are renowned for their vibrant colors and consistency. It is worth trying out a few ink samples to determine which one provides the desired color for the project.

It is a type of ink mainly formulated with pigment particles dispersed in a polymer emulsion. This emulsion enables the ink to flow and spread evenly during the printing process. The inks have water or other solvents as their base, enhancing their ecological friendliness. The most common types of this ink are acrylic and latex emulsion inks. They have a wide range of applications, from textile printing to packaging and offset printing. The ink features quick-drying, high adhesion, and flexibility properties. This makes them ideal for varying substrates, including paper and plastic. These inks can also withstand environmental elements like water and UV rays. They thus ensure the printed designs remain vibrant and durable.

These inks have a greater ecological advantage, particularly the water-based ones. This is because they emit fewer volatile organic compounds (VOCs). This thus reduces the danger to human health and the environment. These inks possess better flexibility and adhesion to various surfaces. This includes hard-to-print surfaces like metal and plastic. They offer superior color vibrancy and resolution. These properties make them preferred options for diverse printing applications. Lastly, they require less petroleum-based solvent. This results in lower production costs while contributing to a more sustainable future.

Yes, some of these inks are strong enough for outdoor applications. UV-cured emulsion inks are particularly designed to resist the sun’s harmful rays. They are ideal for outdoor signage, banners, and vehicle graphics. Additionally, latex emulsion inks also provide great outdoor durability. They are especially recommended for environmentally-conscious outdoor printing. It's worth mentioning that outdoor durability also depends on factors like proper curing and the choice of substrate.

Yes, particularly the water-based emulsion inks do considerably reduce this footprint. They use water as a solvent rather than petroleum-based substances during their formulation. This lowers the reliance on fossil fuels. A portion of the inks is also created using renewable materials. This further contributes to their sustainability. These inks also emit fewer Vocs upon usage. VOCs are greenhouse gases that heavily impact the environment. Their emission is a concern as they contribute to air pollution. Using these inks eliminates them altogether and thus improves indoor air quality.