Introduction to Delta Inverter 380V

The Delta Inverter 380V represents an advanced solution in the realm of variable frequency drives (VFDs). Designed to efficiently manage the speed and torque of three-phase induction motors, this inverter is ideal for a range of industrial applications. With cutting-edge technology and unparalleled performance, the Delta Inverter 380V enables businesses to achieve energy efficiency and optimize production processes.

Types of Delta Inverters 380V

- Basic Drive Models: Catering to essential applications, these models provide reliable motor control with standard features.

- Advanced Drives: Equipped with enhanced functionalities, these inverters are suited for more complex industrial operations.

- Multi-Purpose Drives: Versatile systems that can adapt to a variety of applications, ensuring flexibility for users.

- Specialized Drives: Tailored for specific industries, these inverters offer unique features to meet specialized demands.

Applications of Delta Inverter 380V

The Delta Inverter 380V is versatile and can be applied across numerous industries, providing significant operational benefits:

- Manufacturing: Controls conveyor belts, assembly lines, and production machinery.

- HVAC Systems: Regulates fan speed and improves energy efficiency in heating, ventilation, and air conditioning.

- Pumping Stations: Manages the speed of pumps to optimize fluid movement and minimize energy consumption.

- Textile Industry: Adjusts motor speed for spinning, weaving, and finishing processes.

Features and Advantages of Delta Inverter 380V

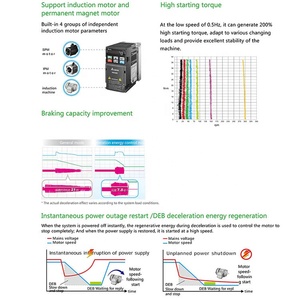

The Delta Inverter 380V comes with a host of features that enhance its functionality and user experience:

- High Efficiency: Designed to provide significant energy savings through its intelligent control strategies.

- Compact Design: The space-saving form allows for easy installation in various industrial setups.

- User-Friendly Interface: Offers intuitive navigation and programming, making it accessible to operators of all skill levels.

- Robust Protection Features: Equipped with over-voltage, under-voltage, and overload protection to ensure safe operation.

- Flexible Control Options: Supports various control methods including V/F control, vector control, and torque control.

- Durability: Built with high-quality materials that ensure longevity and reliable performance even in demanding environments.

How to Choose the Right Delta Inverter 380V

Selecting the appropriate Delta Inverter 380V involves several critical considerations:

- Application Requirements: Assess the specific demands of your industrial application to determine the necessary features and specifications.

- Motor Compatibility: Ensure the inverter matches the specifications of the motor, including power rating and phase.

- Control Needs: Different applications may require different control methods; choose an inverter that suits your operational requirements.

- Budget: Consider the initial cost and potential energy savings over time to determine the return on investment.

- Space Constraints: Evaluate available space for installation, as some inverters might require additional room for heatsinks or airflow.