(4020 products available)

Ready to Ship

Ready to Ship

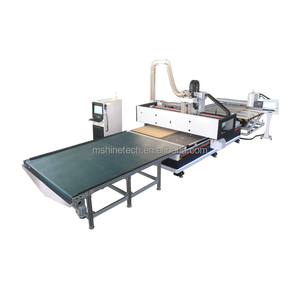

A CNC (Computer Numerical Control) router is a cutting machine used in various industries such as woodworking, metalworking, and advertising, among others. The router is controlled by a computer and is used to cut, carve or engrave materials with high precision. Different types of CNC routers achieve different results and have specific uses.

CNC Router for Wood

This is a standard CNC wood router. Such devices are primarily used in the woodworking industry. The machine is designed to handle wood of different types with precision. It is often used to create furniture pieces, moldings, doors, and other architectural elements. A CNC wood router can be used to work on solid wood as well as wood-based materials like plywood, MDF, and particleboard. An Cooig CNC router 2130 for wood is an excellent addition to any workshop looking to increase production efficiency.

CNC Router for Advertising

This type of CNC router is often referred to as an advertisement CRT or an ad engraving machine. It's designed to cater to advertising companies looking to create signage boards and display stands, among other advertising-related products. This machine can work with materials like acrylic, PVC, and aluminum composite sheets, as well as organic glass. It's no wonder that the advertising CNC router is well-suited for the demands of the advertising industry. Users can rely on its capacity to create precise and high-quality advertising products quickly.

CNC Router for Stone

A stone CNC router is a machine used to engrave or cut stone materials. It is also referred to as a marble engraving machine. This type of router is commonly used in the construction industry as well as in the making of memorials and tombstones. A stone CNC router can be used as a marble, granite, or limestone material. The machine features a strong and robust construction of a metal alloy that can handle heavy stone materials without sacrificing precision.

This machine is ideal for creating complex patterns, designs, and engravings on stone surfaces such as marble and granite. The designs can be of high precision and accuracy, as the router is computer-controlled. With a stone CNC router, users can achieve speed, ease of use, and accuracy.

CNC 2130 routers with specific machine requirements impact the functioning and performance of the device. The following table shows the part and its corresponding specification:

Conrol System:

A robust control system is essential to oversee the entire machining process, from design interpretation to toolpath execution. A suitable CNC control system might include features like a user-friendly interface, compatibility with various file formats, and advanced motion control for precise routing operations.

Motor:

The motor provides the necessary power and torque to drive the router bit for accurate and efficient routing. A CNC motor typically has characteristics, such as variable speed control to adjust the routing speed for different materials and applications and a power rating sufficient to handle the routing tasks without straining or overheating.

Guide Rail:

A guide rail establishes a fixed track for the router to follow during the routing process. The CNC guide rail ensures smooth and precise routing by providing a stable and straight path. The choice of material, length, and diameter for the guide rail may vary depending on the specific routing application and requirements.

Rack and Pinion:

Rack and pinion are the two-part mechanisms that convert rotational motion into linear motion, enabling the router to move along the guide rail. This movement allows for precise positioning and routing of materials. Rack and pinion systems are commonly used in CNC machines to provide accurate and reliable motion control.

Spindle:

The spindle is the component that holds and drives the router bit, enabling the actual routing operation. A CNC spindle is designed to support various router bit sizes and types, providing the flexibility to work on different materials and achieve diverse routing tasks.

Maintenance of a 2130 CNC router is essential for its longevity and optimal performance. Here are some tips on how to take care of the router:

The 2130 CNC router can do a lot of tasks, so it is widely used in many industries and sectors. Because of its precision, efficiency, and versatility, it is a popular choice for various applications that involve cutting, engraving, milling, and shaping materials.

Here are some of the usual usage scenarios of the CNC router machine:

When selecting a CNC wood router machine for a business, there are a number of things to keep in mind, including the work area, because the maximum size of the material that will be processed has a huge impact on production capacity.

Consider the kinds of materials that will be processed. Not all machines can cut through high-density foam, hardwood, or aluminum. Therefore, the machine's structure, spindle strength, and feeding system all influence its ability to process materials.

The machine's spindle speed affects the quality and efficiency of the cut. Higher spindle speeds allow for faster cutting rates, reducing processing time. However, the spindle speed required may vary depending on the type of material and cutting tool used.

A CNC router machine's design and construction determines its rigidity and stability, directly impacting the cutting precision and processing efficiency.

A CNC router's cutting precision determines how accurately the machine can cut materials. Higher precision routers are essential for creating intricate designs. The machine's firmware and software affect its ease of use and the features available. Look for machines with intuitive interfaces and robust software for design and editing.

Choose a router with an appropriate spindle size and power for the materials being processed. The spindle's efficiency affects its cutting ability and the quality of the cut.

A worktable set up for different jobs and easy holding of materials is vital for more productive work.

Data transfer methods, such as DNC (Distributed Numerical Control) and wireless transmission, affect workflow efficiency. Choose a data transfer method that meets the production line or workshop's requirements.

Based on the demands of the business and how often the machine will be used, consider the maintenance requirements and spare parts' availability, so it's a good idea to check the machine's maintenance needs and the availability of spare parts if something goes wrong or needs repair over time.

Q1. What material can a CNC router cut?

A1. A 2130 CNC router is a versatile machine that can cut various materials. Common ones include wood, plastics, composites, aluminum, and soft metals. However, the compatibility of a material with a CNC router will depend on the machine's specifications and capabilities.

Q2. What file types does a CNC router use?

A2. CNC routers typically use files in the G-code format. The G-code is generated from the design software after designing a project in software like AutoCAD or Adobe Illustrator. The G-code contains the commands for the CNC router to follow, including movement, speed, and tool paths.

Q3. Can a CNC router be used for engraving?

A3. Yes. A CNC router can be used for engraving. The machine easily carves materials creating designs, lettering, and patterns on the surface. Owners of the CNC router may have to adjust the depth of the engraving and speed of the router for optimal results.

Q4. Can a CNC router be used for ad sign making?

A4. A CNC router is often used in the creation of advertisement signs. It can be used to cut, carve, and engrave a wide range of materials, such as wood, acrylic, PVC, and aluminum, to make different kinds of signs. The router also allows for customization, enabling the creation of unique sign shapes and designs. As a result, businesses can create highly professional signage for their brand or business.

Q5. Does a CNC router need a dedicated computer?

A5. Unlike other CNC machines that require a computer to run the design and routing process, a CNC router does not need a computer at its control system. The machine can have its control system that allows it to be controlled and directed to the routing pattern without a computer. However, connecting a computer to the router can be useful in designs requiring complex and more sophisticated routing patterns.