(9050 products available)

A CNC rotary table is a work positioning device used in CNC milling machines to provide the workpiece with multiple angles and automate workpieces for various parts. The generally accepted definition of a rotary table on Google is a tabletop that turns on a horizontal axis, usually for advertising, displaying merchandise, or instruction purposes.

CNC (computer numerical control) tables are crucial components in CNC machining, especially in the wood and metal industries. They come in numerous forms to serve specific purposes, with two major groups, fixed and tilt tables:

Dimension

-For small tabletop CNC machines, the rotary axis usually has a table dimension of about 300mm or less.

Compatible CNC Models

-The rotary CNC table has to connect with the standard 3040, 6040, and 6090 CNC machine models. It will usually have a mount that matches the table's frame.

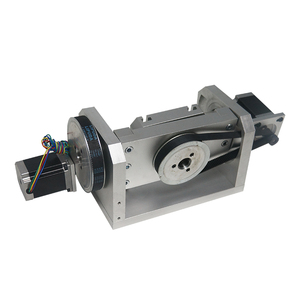

Driving System

-Most rotary axis tables use stepper motors as their driving system. These motors are usually NEMA 23 with a specific gearbox ratio to provide the desired speed and torque.

Payloads

-Small rotary CNC tables generally support weight capacities of around 5-8kg. Heavy-duty ones may allow up to 15kg or more.

Lubricate the Rotary Table:

CNC machinists should grease the CNC rotary axis regularly. They should add lubrication to the rack and pinion or belt and pulleys. Greasing them reduces friction and prevents wear and tear. Therefore, standards of quality, precision, and performance are maintained.

Ensure Proper Alignment:

Frequent checks should be made on the alignment of the rotary CNC axis against the machine's vertical and horizontal planes. Misalignment can negatively impact cut quality and precision. If any adjustments to the table's mounting brackets are required, make them promptly. Realignment after any undue table displacement is also necessary. This will ensure that the rotary axis remains level and aligned precisely within the framing of the CNC machine.

Clean the Worktable Surface Area:

It's always a good idea to routinely clean the work surface of the rotary table to remove dust, debris, and other build-up. A clean worktable allows for proper component clamping, accurate alignment, effective vacuum hold-down, and optimal cutting quality. Using the rotary axis to CNC-machine multi-object setups is a great way to improve production efficiency. Remember to keep all work surfaces clean and tidy, even those that are often not used during normal operations.

As an accessory to the CNC router machine, the cnc rotary table axis gives extra dimension to the machining process. While the fixed horizontal and vertical workpieces are the typical ones that can be worked on, the rotary table makes it possible to work also on cylindrical objects like columns.

The rotary table can be used to engrave or to do relief carving on columns, cylindrical wood, metal objects, mugs, gun parts, jewelry, and other similar objects. The engraving may be of intricate patterns, logos, letters, or any other desired design. Using the CNC rotary table adds value to the object being worked on with personalized and custom designs.

Rotary CNC engraving is a common use for this accessory. The CNC machine and rotatory table can be used on many different materials like wood, metal, glass, stone, crystal, PVC, and aluminum, to name a few. One of the major benefits of the rotary table is that while the CNC machine does its work and creates the desired design on the object, there is no need for any extra manual work or operator intervention.

The types of goods that can benefit from the CNC rotary table include, but are not limited to, the following industries:

When shopping for a CNC rotary axis table for sale, a consumer should start by researching popular brands and products in the industry. This will help them understand what tables people use, their preferences, and the features they prioritize. If shopping for a small tabletop CNC rotary axis for a specific item such as a gun kit, a consumer may want to buy a dual or triple axis that could also handle other products in the inventory.

When choosing a CNC rotary table, it is essential to match the tabletop axis machine with the existing CNC machine. Most manufacturers build their machines to work with their products. However, it is also good to look into the table's software capabilities. When the software of the two machines is compatible, the two machines can work together efficiently.

A consumer should also determine whether they want a driven or passive rotary CNC table. A passive table may be suitable for small businesses with limited capacity, while a driven table will work better for higher production levels. Consider how often the table will be used and its workload. That same logic can also be applied to a hold-down mechanism. Pneumatic hold-downs work better for businesses with higher capacity and more frequent tabletop use.

When determining how much work the rotary axis table will have to do, also consider the size and weight of the objects it will hold. Heavy, large, or bulky items will require more torque, load capacity, and horsepower.

Apart from the machine's torque and load capacity, customers will also look at the tabletop's motor, accuracy, and repeatability. Motor speed requirements differ, but generally, slower speed is preferred for better precision, while high speed is ideal for better production.

The warranty period on a product can also determine its purchase. Customers will want to buy products they can replace or repair if something goes wrong within the warranty period. Comparing the warranty period offered by different manufacturers will guide the decision-making process.

Q1: How to choose a proper CNC rotary axis?

A1: Workpiece compatibility is the priority. Ensure the axis can handle the size and weight of the workpieces. Then, match the rotary table's axis with the CNC machine's spindle taper and diameter. The connection must be secure and stable. Furthermore, consider the available drive systems, whether it's a direct drive for high torque and compactness or a belt drive for a cost-effective solution. Finally, the resolution and quality of the rotary encoder affect the precision of the axis's rotations. Choose an encoder that meets the project's requirements.

Q2: Can a rotary axis be added to any CNC machine?

A2: Not all CNC machines can support a rotary axis. The machine must have the necessary control and drive capabilities. However, some retrofitting or modification might allow the addition of a rotary axis.

Q3: Are all CNC rotary axes the same?

A3: No, there are different types of rotary axes designed for specific applications. Nonetheless, they all share a similar basic function: to provide rotation for the workpiece.

Q4: Can a rotary table be added to an existing CNC machine?

A4: In some cases, it's possible to add a rotary table to an existing CNC machine. However, the complexity and cost of the table will be high, and it may require additional controls and software to operate the rotary axis properly.