(92 products available)

An Automated Liquid Handling System is a machine that performs the transfer of small quantities of liquid between different vessels, tubes, and wells. These systems are available in a variety of types, each suited to distinct purposes and requirements. A few types of automated liquid handling systems are detailed below.

Pipetting robots are one of the most common types of liquid handling systems. They are designed to mimic the functions of manual pipettes and are used to dispense precise volumes of liquid. They can be divided into air displacement pipettes and positive displacement pipettes. The former is suitable for general liquid handling, while the latter is better at dealing with volatile, viscous, or dense liquids by using a disposable tip. Single-channel pipettes can transfer one liquid at a time from different containers, while multi-channel pipettes can handle several samples simultaneously. Pipetting robots can be controlled by software to program and repeat liquid-handling tasks with high accuracy and precision.

Automated dispensing systems are used to accurately dispense liquids into containers or other surfaces. They can be divided into contact and non-contact systems. Contact dispensing systems include positive displacement pipettes, syringe pumps, and dispensing tips. They operate by physically touching the target surface, ensuring precise volume control. Non-contact dispensing systems, such as piezoelectric, inkjet, and spray technologies, work without touching the target surface. They rely on air pressure or other mechanisms to propel the liquid, allowing for high-speed dispensing and preventing sample contamination.

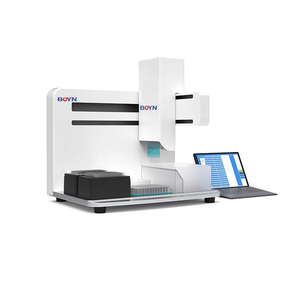

Integrated liquid handling workstations combine multiple liquid-handling functions in one machine. They can perform liquid transfer, mixing, dilution, plate replication, and other tasks. Integrated workstations usually come with various liquid-handling tools, such as pipettes, washers, dispensers, and readers. They are also equipped with a robotic arm for sample preparation and analysis. The system is controlled by user-friendly software, allowing for automated operation and data analysis. Integrated workstations are suitable for high-throughput screening, drug discovery, and other applications.

Automated liquid handling platforms are systems that automate the process of transferring, aspirating, and dispensing liquids. They can be divided into modular and standalone systems. Modular platforms allow users to customize and add different liquid-handling components according to their needs. Standalone platforms are integrated systems that combine multiple liquid-handling functions into one machine. Both types of platforms are controlled by software and are capable of performing high-precision liquid-handling tasks. They are suitable for various applications, including genomics, proteomics, drug discovery, and clinical diagnostics.

Capacity: Automated liquid handling system has a high-throughput processing capacity. Depending on the model and configuration, it can handle different liquid volumes, ranging from microliters to milliliters per cycle. The total volume of liquid that the machine processes in a day can be several liters to hundreds of liters.

Adaptability: The automated liquid handling system is compatible with different types of containers, such as test tubes, vials, plates, and syringes. The system can accommodate various sizes and formats of containers, from small tubes to large plates, depending on the application requirements.

Software: Automated liquid handling systems are equipped with advanced control software. This software allows the user to create and optimize liquid handling protocols, set parameters for volume, speed, and accuracy, program the system for specific tasks and integration with other devices, and monitor and analyze the data in real time.

Accuracy and precision: Automated liquid handling systems provide precise and accurate liquid transfer. The system's pipettes, dispensers, and pumps are calibrated to ensure consistent and reproducible results. The precision of the system is in the range of 0.1% to 1%, depending on the type of component and the calibration method.

Integration: Automated liquid handling systems are easily integrated with other laboratory equipment. The system can be connected to devices such as plate readers, incubators, and analyzers to create automated workstations and complex workflows.

Calibration: Regular calibration of the system's liquid-handling components (e.g., pipettes, dispensers, pumps) is necessary to maintain accurate and precise liquid transfer. Users should follow the manufacturer's recommended calibration procedures and schedules.

Cleaning: Regular cleaning of the system's components and surfaces is necessary to prevent contamination and maintain performance. Users should use compatible cleaning solutions and follow the manufacturer's instructions on how to clean the system.

Preventive maintenance: Scheduled preventive maintenance is essential to ensure the system works properly. This includes checking and replacing worn parts, such as seals and filters, lubricating moving components, and performing diagnostic tests. Users should follow the manufacturer's maintenance schedule and procedures.

Software updates: Regularly updating the system's control software ensures stability and new features and improvements. Users should remain alert to software updates released by the manufacturer and follow the recommended update procedures.

System integrity: Users should frequently inspect the system for signs of damage, wear, or leaks. If there are any issues, they should immediately address them and contact the manufacturer or an authorized service provider for help.

An automated liquid handling system is widely used in various industries and research fields that require precise liquid handling and high-throughput processing. Here are some typical application scenarios.

In drug discovery, automated liquid handling systems can precisely dispense compounds, reagents, and samples for high-throughput screening, assay development, and compound management. This accelerates the pace of drug discovery and development.

In clinical laboratories, these systems can automate the sample preparation, as well as the transfer and mixing of samples with reagents. This can improve the efficiency and accuracy of diagnostic testing.

For genomic and proteomic research, automated liquid handlers can precisely dispense nucleic acids, proteins, and other biomolecules for tasks such as PCR, sequencing, and protein analysis. This ensures the reproducibility and reliability of experimental results.

In the food and beverage industry, automated liquid handling systems can be used for tasks such as flavor formulation, quality control, and sample preparation. This ensures consistency in product quality.

For environmental monitoring and analysis, automated liquid handlers can automate the extraction and analysis of contaminants in water, air, and soil samples. This improves the efficiency and accuracy of environmental testing.

In academic research institutions, automated liquid handling systems can be used in a wide range of fields, including biology, chemistry, and material science. These systems can automate experimental workflows, such as reaction setup, compound screening, and assay development. This frees researchers from repetitive manual pipetting and enables them to focus on data analysis and interpretation.

When choosing an automated liquid handling system for any application, the first step is to define all the tasks that the system will perform. These tasks will include everything from pipetting and mixing to capping and decapping. By listing all the tasks that need to be done, it becomes easier to choose a machine that can do them all. This will reduce the number of processes the liquids will go through, thereby increasing efficiency and decreasing the chances of making errors.

The next thing to do is to determine the required throughput capacity of the liquid handling system. This includes the volume of liquid to be processed, as well as the number of samples or total volume that will be worked with daily. It also includes the required speed of the system. Knowing these will help to choose a machine that can handle the required volume and speed of the work. If the machine is too slow or too small, it can hinder the smooth running of the laboratory.

Another thing to consider is to determine if the type of liquid and the container material to be used will be compatible with the chosen liquid handling system. This is particularly important for sensitive samples such as DNA and RNA, as well as for corrosive and volatile chemicals.

Finally, consider the ease of use, service, and support for the chosen liquid handling system. Look for intuitive software, training, and technical support options to ensure successful implementation. Also, consider the maintenance and calibration requirements of the system to ensure smooth operation over time.

Q1: Are automated liquid handling systems compatible with various types of containers?

A1: Yes, automated liquid handlers support a wide range of container types. These include vials, tubes, plates, and various well formats. Automated systems are easily adaptable to different types of containers. For instance, liquid handlers can be equipped with interchangeable tools, such as grippers and pipette tips, that can be customized for specific container types.

Q2: Can an automated liquid handling system dispense liquids of different viscosities?

A2: Automated liquid handling systems can dispense liquids with varying viscosities. Such machines can accommodate thick, thin, and even volatile liquids. Liquid handlers equipped with the appropriate components and control settings such as positive displacement pipettes or specialized tips can handle different viscosities.

Q3: Are automated liquid handling systems easy to calibrate and validate?

A3: Automated liquid handlers are generally considered easy to calibrate and validate. Manufacturers provide clear calibration and validation procedures in the user manuals. Many liquid handling systems also have built-in self-calibration routines that simplify the calibration process. Additionally, service providers offer assistance and guidance when calibrating and validating liquid handlers.