(259 products available)

A 5th axis CNC machine involves many different types of rotary tables that allow intricate and advanced movements for superior products. Here are some of the commonly known ones:

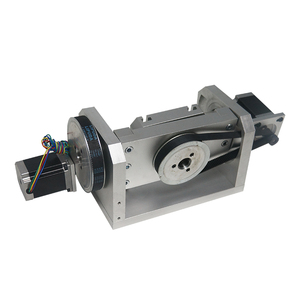

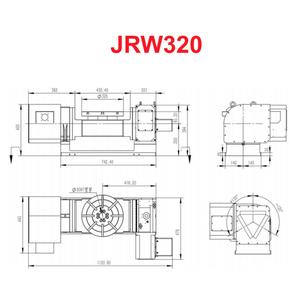

Toothed belt-driven rotary table

The basis of the belt-driven rotary table lies in the use of a toothed belt and its pulleys to allow movement. One of its advantages include that it can provide great axis speed with relatively low inertia. This allows for quicker acceleration and deceleration, as well as higher feeding rates. Machine operators can enjoy the table's functionality with almost silent operation and little maintenance needs from regular lubrication. The belt-driven rotary tables ride on rails and can, therefore, offer a larger working area.

Pneumatic rotary table

The movement of the rotary table is controlled and moved through pneumatic power. This means that the table relies on pressurized air and compressors to conduct different tasks. One advantage of this is that the operator or machinist can attain high torque at low speeds. The durability of this system is commendable, as it can be used in harsh environmental areas and still give a good level of accuracy. Furthermore, it can be used for large and heavy workpieces. Of course, the precision and quality of the product depend on the quality of the air and the regular maintenance of the compressors.

Harmonic drive rotary table

The movement of this rotary table is based on a harmonic drive system. Some advantages include the high reduction ratio and even more impressive accuracy it can provide. It is known for having high stiffness and a zero backlash feature. Therefore, making it easy for machines to use it for exceedingly precise applications that demand a high level of detail.

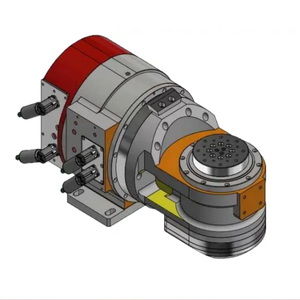

Direct-drive rotary table

This type of drive uses a gear drive and motor to make it rotate. The tables offer easy integration with CNC systems. This allows for smooth and reliable operation to suffice even the most demanding jobs. Additionally, the gear and motor drive system provides high torque and acceleration. The direct-driven rotary table is one of the most accurate and high-torque tables available for use. It achieves all of this while also having a low-profile design and increasing axis usability and flexibility.

Worm-driven rotary tables

For worm-driven rotary tables, the worm gear drives the table to allow it to move. The gear is compact and can withstand large loads. It also provides great rotational range." The durability of this gear allows it to be used in heavy industries and for the machine to still function without any hitches.

5-axis machines come in different specifications depending on the producer and intended use. When looking for an axis CNC machine for sale, one can find several configurations with distinct specifications.

5th axis CNC machines are costly and complex devices, requiring meticulous maintenance to ensure consistent optimal performance. Below are the maintenance measures buyers or operators can consider to keep the machines in pristine condition:

CNC 5th Axis Rotary Tables are widely used in various industries, including aerospace, automotive, architecture, electronics, medical, and jewelry, CNC machining, and prototyping. Here are some of their most common applications:

Production demand analysis

First, it is necessary to determine the required rotation speed. When choosing a 5-axis CNC rotary table, one should consider the premise of the highest rotating speed of the workpiece the machine can accommodate. The maximum rotating speed of the rotary table should meet the requirement of the cutting speed of the processed workpiece.

Structural types

Both the A-axis and C-axis can be divided into different structural types, such as worm gears, direct drive, belts, and other types. Among them, the direct drive motor can achieve high acceleration and deceleration speed and high rotation speed. It also has high positional accuracy and a compact structure.

Loading capacity

Another important factor when selecting a 5-axis CNC machine rotary table is the maximum load moment. One should choose the load capacity according to the weight of the workpiece and the machine tool's inertia. A higher load capacity can provide more stability and precision when machining heavier workpieces.

Control method

Under this premise, it is important to choose a rotary table that matches the control system of a CNC machine or an independent controller. It is also important to ensure that the communication protocols are compatible and that the programming and operating interfaces are easy to use.

Accuracy requirements

The accuracy and resolution of the rotary table are also essential things to consider when selecting a 5-axis CNC machine rotary table. A high-precision 5th-axis CNC rotary table can achieve high positioning accuracy and repeatability, ensuring that the workpiece is processed with high precision.

Budget

Finally, a 5-axis CNC machine rotary table with a larger load capacity and a higher degree of accuracy and complexity is expensive. So budgeting is also an important part of choosing.

Q1: What are the advantages of using a 5th axis CNC machine in machining applications?

A1: The five-axis CNC machining has numerous advantages. To begin with, it allows continuous rotational freedom of the tool, creating complex and precise geometries. Additionally, five-axis machines improve work efficiency by reducing tool change. They also facilitate the use of high-speed machining techniques. Another advantage is that machines with five-axis capabilities offer increased accuracy and tight tolerances.

Q2: Can a 3/4th axis CNC machine be upgraded to a 5th axis?

A2: In most cases, yes. Upgrading a CNC machine from 3/4th to 5th axis may involve adding rotary tables and other complex components. It may also require a substantial upgrade to the machine's control system.

Q3: What types of materials can a 5th axis CNC machine work with?

A3: The 5th axis CNC machine can work with multiple materials, including metal alloys, plastics, wood, and composite materials.

Q4: What factors to consider when buying an aftermarket 5th axis attachment?

A4: Several factors should be considered, including compatibility with the existing CNC system, the quality of the components, its accuracy and repeatability, its work envelope and load capacity, and its control integration.