(16809 products available)

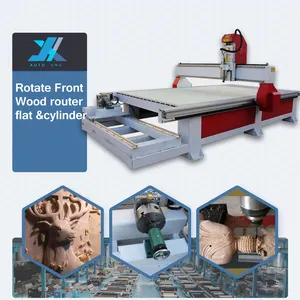

A 4 axis CNC router with servo motors differs from those using a stepper motor system, as they have an electromagnetic motor that provides a vital holding torque and allows for smoother movement with speed and precision. The four-axis CNC router machine also includes a rotational or tilting axis that allows the router to move or rotate along an additional axis and increase the machine's working capacity. Below are some types of 4 Axis CNC Routers:

4 Axis CNC Router with Gearbox Servo Motor:

Gearboxes are standard components of servo motors that support torque. They are helpful for positioning heavy workpieces or needing a low rotational speed. A CNC machine with a gearbox will have a belt or chain drive usually connected to the servo motor.

4 Axis CNC Router with Simple Servo Motor:

This motor does not have a gearbox connected to it. It is a direct drive that uses conventional bearings. A direct drive allows the workpiece to spin easily.

4 Axis CNC Router with Spindle:

A spindle refers to a shaft in a machine that allows the workpiece to be held in place while router cuts or carves are done. Spindles come in two forms in a 4 axis CNC router: as a work holding device with rotary cutting tools and as the motor that turns and powers the shaft containing the rotary cutting tools. Standard routers use wood and aluminum. An AC motor usually powers them, which provides high speed and is used for light-duty work. A 4 axis metal CNC Router machine will more likely have a servo motor spindle that works for heavy-duty projects.

Automatic Tool Changer (ATC) 4 Axis CNC Router:

An automatic tool changer is a device that automatically changes the router bit or tool used while machining or cutting a workpiece as needed. It is fastened to the spindle of the CNC router and can hold multiple tools. The ATC eliminates the need for manual changes and increases or improves machine productivity. The tool changer can be fixed, as in a vertical setup, or rotary, as in a carousel.

4 Axis CNC Router with Plasma:

A plasma cutter is used to make precise and clean cuts in materials using ionized gas or plasma. The device creates an electrical channel in the cut area that feeds and uses the lightning and heat from the plasma to perform the cut. A 4 Axis plasma CNC router can give workpieces that have been cut a clean and smooth quality unparalleled by other cutting techniques.

The specifications of a 4-axis CNC router vary based on its make and model. Nonetheless, some key features are shared across most routers.

To ensure optimal performance, customers should adhere to a well-defined maintenance schedule. This entails infrequent checks for possible mechanical issues, such as loose bolts and belts, alignment and calibration of the machine parts, and cleaning and lubrication of the moving sections to prevent dust and debris buildup. Also, users should promptly update the machine control software to take advantage of advanced features and enhance performance.

The 4-axis CNC router with a fourth rotation axis is a versatile and powerful machining tool with many applications. Some typical usage scenarios include but are not limited to the following:

Business needs assessment:

To begin with, buyers should evaluate their particular business requirements. It includes checking the type of materials they typically use and their size. Also, consider the complexity of the shapes and the precision they need to achieve. They may also need to think about their existing machine infrastructure, like whether it's compatible with a 4-axis CNC router servo.

Signals and drive compatibility:

Choose a 4-axis CNC router servo that matches the controller's signal and drive requirements. Consider the communication protocols, such as Ethernet, CANopen, or EtherCAT, which allow for smooth data exchange between the controller and the servo motors. Additionally, ensure that the servo motor drives are compatible with the selected CNC controller, considering factors like motor pairing and drive capabilities.

Power and torque:

Users need to determine the required power and torque of the 4-axis servo motor based on the materials they typically work with. For heavier materials or more demanding applications, they might need servos with higher power ratings to ensure adequate torque for smooth and precise cutting. They should also consider factors like acceleration, deceleration rates, and load requirements to achieve optimal performance for their specific machining tasks.

Quality and support:

Finally, it's crucial to invest in a good quality product. Choose a 4-axis CNC router servo from reputable brands that offer strong customer support and good feedback from other users. Research the supplier of the 4-axis CNC router and its servos. In the case that the customers need technical help or spare parts, they should be sure to receive timely assistance.

Q1: What are the benefits of a 4 axis CNC?

A1: The extra A-axis in 4 axis CNC routers allows for greater workpiece rotation and manipulation. This feature provides some advantages, such as less workpiece setup, the ability to carve deep into objects, higher productivity, and more intricate 3D contouring and carving.

Q2: What materials can 4 axis CNC routers work with?

A2: The 4 axis CNC machine is ideal for wood and acrylic material but not limited to any specific material. They can also be used to work on various materials like soft metal, PVC marble, etc., with the appropriate cutters.

Q3: Do 4 axis CNC routers have any limitations?

A3: While 4 axis CNC routers offer advanced capabilities, they may have limitations. The added complexity of the fourth axis can make machines more expensive. Additionally, 4 axis CNC machines also require more maintenance compared to their 3-axis counterparts. Moreover, learning to operate and program them may take longer for new users.