(437 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

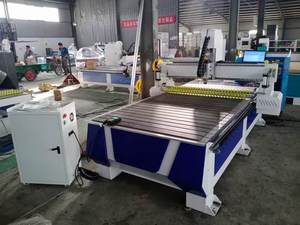

CNC routers are popular tools that use computer numerical control to cut and shape different materials precisely. A 1515 CNC router is usually referred to as a small-format CNC router. It is scaled-up version of a typical 1212 CNC router. Like other CNC machines, the 1515 CNC routers come in various types, each suited for specific tasks and materials. Here are some of them:

Users can maximize the performance and lifespan of the 1515 CNC Router by regularly performing maintenance tasks. Here are some critical 1515 CNC Router maintenance tips:

Clean the router regularly

It is essential to get rid of any dust, debris, or residue that may have accumulated during use in order to maintain its peak performance. Cleaning the work area, router bit, and vacuum cleaner for dust collection is necessary. One can also wipe the router's exterior using a soft cloth and mild detergent.

Lubricate moving parts

Apply a small amount of high-quality lubricant to the rail, lead screw, and bearing grease regularly so as to ensure smooth movement and reduce friction on the router. Lubricating the moving components can also help users avoid rapid wear and tear, which may affect the lifespan.

Check for loose bolts and screws

Regularly inspecting and tightening any necessary components, such as bolts and screws, is necessary to maintain the CNC 1515 Router's stability and accuracy. This can help the router avoid unnecessary vibrations or even damage that may result from loose components, thus maintaining its function and precision.

Inspect and replace worn parts

During use, some components may wear out or become damaged, such as the router bit, bearing, and guide rails. Therefore, one should regularly check these parts to ensure they are in good condition. If not, it's best to replace them immediately to avoid affecting the overall performance and quality of the engraving.

Maintain the cooling system

If the 1515 CNC router is water-cooled, it's essential to check the coolant level and add it as needed to avoid overheating the machine during operation. Also, ensure that the cooling fan functions properly and the cooling system is clean.

Back up and protect data

It is crucial to back up the designing data and tool paths regularly to avoid unintended loss or damage. Using a surge protector can also help shield the CNC router from electrical surges and fluctuations.

Maintain proper operation

Users have to apply the router per the operating instructions and specifications. Avoid exceeding the recommended rotation and feed rates so as to prevent damage and maintain good performance. Also, try to minimize the temperature and humidity fluctuations during storage, which can help protect the router from damage.

The 1515 CNC router has a wide range of applications across various industries. Here are some of the most common uses and purposes of this machine.

Woodworking projects:

CNC routers are often used for woodworking. Therefore, they are ideal to use for precise cutting, carving, and engraving of different wooden materials. This includes MDF, plywood, and solid wood. The machine can be used to create complex joinery, intricate patterns, decorative moldings, and custom signage.

Prototyping and product development:

The CNC router is commonly used in product development and prototyping. The machine can be used to create prototypes for testing and evaluation. It allows designers and engineers to fabricate components with precision and speed. This helps them to iterate design and make necessary changes before moving to the final production phase.

Model-making and architectural design:

CNC routers can be used to make architectural models and designs. This includes landscape features, topography, buildings, and urban layouts. This allows architects to visualize their projects. Also, the machines can be used to create cut patterns and templates for their work.

Metalworking:

1515 CNC routers equipped with the right cutters and spindles can be used for light metalworking tasks. This includes working on aluminum, brass, and plastic metals. Such materials can be routed, engraved, or cut using the CNC router with precision.

Composite materials and plastics:

1515 CNC routers can be used to cut and mill composite materials like fiberglass and carbon. The machine is also great for precision cutting, engraving, and routing of plastic materials.

Musical instruments:

CNC routing technology can be used in the musical instrument industry. The machine can be used to create custom parts for musical tools such as guitars, violins, and drums. It can also be used in inlays and elaborate designs.

Cabinetry and furniture making:

A Furniture maker presents a CNC routing job. The operator can use the machine to make intricate cuts, joinery, and designs for different furniture pieces. Also, the cabinetry maker can use the device to create custom cabinets with precision features and doors.

Jewelery making:

A jeweler can use the CNC router to make a precise cut of delicate materials. This includes engraving, cutting, and designing the jewelry pieces with intricate patterns and personalization.

When purchasing a 1515 CNC router, buyers will need to choose the right router for their specific needs. The following factors will have to be considered:

Materials and Applications

As mentioned earlier, 1515 CNC routers are capable of working with different types of materials. Also, they perform various machining tasks. For this reason, buyers will have to consider the materials their business works with, as well as, the applications before choosing a CNC router. Once the materials and applications are determined, choose a 1515 CNC router that is designed to work with them.

Machine Specs

Among the most important decisions buyers have to make is choosing a router based on its specifications. To match their needs, buyers will want to consider the machine specifications, including the work area, spindle power, accuracy, control system, and speed.

Buyers will want to choose a router that has a work area that matches the dimensions of the projects they will be working on. Also, they will want to choose a router with a spindle that has enough power for the type of material they will be working with. Furthermore, buyers will want to choose a router that has enough accuracy to deliver the level of precision their projects require.

In most cases, 1515 CNC routers come with user-friendly control systems that are easy to operate. This is a good thing since it allows users to navigate the software with ease. Nevertheless, if the buyer’s staff will require some training, it is a good idea to invest in training before purchasing the router.

Budget

Apart from the specifications and features of a 1515 CNC router, buyers will also want to consider their budget. Once buyers set a budget, they can begin comparing different models and finding a router that will meet their needs and is within their budget. To ensure they are getting good value for their money, buyers will want to take the time to research reputable manufacturers and suppliers.

Q1: Is a 3D CNC Router capable of cutting metal materials?

A1: It depends on the capability of the CNC Router. Smaller Router models like the 1515 are not suitable for metal cutting due to their low power and small spindle sizes. Nevertheless, larger models with powerful motors can cut light metals such as aluminum and brass.

Q2: What Router is suitable for newbie CNC users?

A2: CNC users can choose between different types, sizes, and variants. However, a safe option for beginners is a desktop CNC Router. It is user-friendly, affordable, and suitable for learning CNC basics. Moreover, desktop Routers have a safe working environment that protects users from hazards.

Q3: How can CNC users achieve a smooth finish on their workpieces?

A3: The secret to achieving a smooth finish lies in the selection of the right Router bit. Users should also choose the correct feed rate, depth of cut, and RPM. Lastly, employing a finishing pass during the Router's operation will enhance the final surface finish.