(11 products available)

A 1312 CNC router is a small-sized CNC router that works perfectly for light-duty materials. Generally, CNC routers are available in various models and sizes to suit different needs. Here are the most popular types of CNC routers:

Tabletop CNC routers:

Tabletop CNC routers are small and compact devices typically designed to fit on a bench or workstation. Despite their small size, these CNC routers provide features and capabilities similar to larger models. This includes a sturdy construction, an easy-to-use control panel, and various routing functions. Because of their compact size and affordability, tabletop CNC routers are suitable for hobbyists, DIY enthusiasts, and small workshops requiring professional machining power in a limited space.

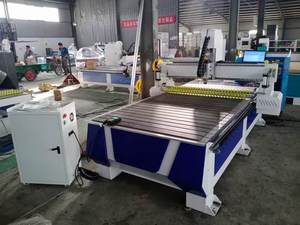

1312 CNC router:

As mentioned earlier, the 1312 CNC router is a small-sized router best for desktop use. It features a working area of 1300mm x 1200mm, which provides достатньо space for routing, cutting, and engraving lightweight materials. One of its notable features is the support for different file formats, including JPG, DXF, BMP, TIF, NC and GIF, making it easy to convert designs into machining instructions. The 1312 CNC router is suitable for businesses and individuals in advertising, furniture, decoration, and DIY projects.

Lead CNC routers:

These CNC routers use lead screws on their axes to move the cutting tool. The design provides accurate and precise cuts. It is mainly used in light to medium-duty applications, allowing businesses to work on wood, metal, plastic, acrylic and foam. Moreover, lead CNC routers are available in different table sizes to suit various needs and come with additional accessories such as dust extraction systems and automatic tool changers.

ATC CNC Routers:

Also known as Automatic Tool Change CNC Routers, these machines come with an automatic tool changing system. The system enables the router to change its cutting tools automatically during the machining process. Because of this feature, ATC CNC routers are perfect for applications that require multiple tooling operations, such as complex engraving, carving, and detailed work. Besides, they are mostly used in industrial manufacturing settings.

4 Axis CNC Routers:

Unlike conventional CNC routers that only have three axes (X, Y, and Z), 4-Axis CNC Routers incorporate an additional rotational axis. The additional axis allows for more complex machining operations, including carving and engraving on cylindrical objects. 4-Axis CNC Routers are mostly used in architectural projects, design industries, sculpture works and high-precision engravings.

The 1312 CNC router has a reliable router with a power of 800W to 2.2 KW. Its maximum speed is 24000RPM. The 1312 CNC router's working area is 1300mm X 1200mm X 200mm, suitable for large workpieces. Its cutting thickness is 0-200mm. The x-axis and y-axis structural beams are made of aluminum alloy, whose width is 7.5cm, achieving high accuracy in processing. The machine base is a sturdy square tube structure. It is an ideal choice for heavy-duty jobs. This machine's control system offers user-friendly software and smooth operation. The 1312 CNC router also has dust removal and cooling systems for a clean and safe environment.

Regular maintenance can help users keep the 1312 CNC router in top condition and extend its service life. The following are some important maintenance tips:

CNC routers with 1312 specifications have diverse applications in various industries. They are widely used in sign-making shops to cut materials like plywood, MDF, plastic, and acrylic into different shapes and sizes. The devices let users create customized and high-quality signage, letters, and even logos.

They are also used in furniture-making companies to produce components like tabletops, doors, and cabinets. The devices help achieve precision in detailing and cutting complicated designs, resulting in both efficient and beautiful final products.

CNC routers are also used in carpentry workshops to trim panels and boards to the desired dimensions. They are also used to carve large workpieces like arches, beams, and frames. Generally, these machines improve accuracy, reduce waste, and save time.

In modeling and prototyping companies, the CNC routers can be used to cut and mill different materials to create architectural models, scale prototypes, and product models. They can also be used to explore new design concepts or for validation of functional designs.

The routers can be used to engrave complicated patterns on different materials like gaskets, copper, Mylar, and brass. They are also used to engrave for arts and crafts on resin, wood, glass, and metal. These devices allow for intricate and detailed designs that are hard to achieve by hand.

CNC routers with 1312 specifications are also used in the aerospace and automotive industries to cut lightweight composite materials and aluminum. In these industries, such routers might be programmed to automatically cut complex geometries to enhance accuracy and minimize weight.

The devices can also be used to create stencils or templates for the support system during the assembly of electrical components. In this case, CNC routers can be more convenient than traditional manual cutting methods.

Finally, 1312 CNC routers are used in educational institutions to teach students about digital fabrication and CNC technology. In such cases, the machines are used to do simple projects or collaborate with others to develop more complex projects.

When choosing a 1312 CNC router, it is crucial to understand the target market's requirements and preferences. Take time to consider factors key to the machine's functionality, such as the material it's built to work on, cooling system, spindle motor power, accuracy and precision, controller system, work efficiency, and vacuum pump strength. While these factors are pertinent to the machine's operation, they are also essential to answering the questions of potential buyers.

Investigate the kinds of materials various 1312 CNC routers work on and know if the machine is capable of working on different materials or if it's designed to handle only specific materials, such as wood or metal. Also, be aware of the machine's limitations when it comes to material type, thickness, and density. As earlier explained, cooling systems play a crucial role in the smooth operation of a CNC machine. Depending on the materials the router will be working on, determine the kind of cooling system–air or water–that will be used.Stay informed about the advantages and disadvantages of both systems.

Remember that the spindle motor gives the 1312 CNC router the ability to operate at different speeds. It's also pertinent to know that motors with higher power ratings tend to work with heavier materials and have longer lifespans. While considering the spindle motor power, consider the router's accuracy and precision. Some focus on achieving high-speed operations, while others prioritize accuracy. Determine which of these should be prioritized when selecting a CNC router.

The user controls the 1312 CNC router through the router's controller system. Different CNC routers have varied controller systems, and understanding these will help make an informed choice that meets the target market's requirements. More importantly, compare the work efficiency of different CNC routers and understand how this affects overall productivity.

If interested buyers work in an industry that demands strong vacuum pumps, go with a router that has a motor power of at least 2.2 kW. Such a motor strength will provide a strong grip on materials to cut. Finally, it's insightful to know whether the CNC machine is a portal or an engraver type. Each type has a preferred area of application.

Q1. What types of materials can a 1312 CNC router work with?

A1. A 1312 CNC router is primarily designed to cut and shape materials like wood, MDF, acrylic, PVC, plywood, foam, and soft metals such as aluminum and brass. While it can work with some metals, it is not suitable for harder metals like steel.

Q2. How precise are 1312 CNC routers?

A2. CNC routers are known for their high precision and accuracy, with typical tolerances ranging from 0.1mm to 0.01mm, depending on the machine's quality, the software used to control it, and the technician's expertise.

Q3. Can a 1312 CNC router be used for 3D machining?

A3. Yes, a 1312 CNC router can be used for 3D machining provided it has a Z-axis travel sufficient for the 3D operation to be carried out. Nevertheless, not all 1312 CNC routers are suitable for 3D machining. Ideally, you should check the router's specifications to ascertain its suitability for 3D machining.

Q4. What software is commonly used to program a 1312 CNC router?

A4. The software commonly used to program a 1312 CNC router varies depending on the machine's manufacturer. Nonetheless, most CNC routers use CAD/CAM software for design and toolpath generation. Some popular CAD/CAM software includes ArtCAM, Router Engraving Machine Software, Mach3, and Aspire.

Q5. Can I modify a 1312 CNC router with additional attachments?

A5. Yes. You can modify a 1312 CNC router with additional attachments, such as a laser engraver or a rotary axis, to expand its capabilities. However, you should consult with a knowledgeable technician to ensure that the router can be modified and that the attachments are compatible with it.